GEP ECOTECH's single-shaft shredders excel at fine shredding, ideal for recycling and producing alternative fuels. With multiple equipment series designed to thrive in challenging environments, we offer versatile solutions for diverse production needs. Rely on GEP ECOTECH for premier, high-performance shredding solutions, meticulously crafted using advanced technology and stringent manufacturing standards.

Send

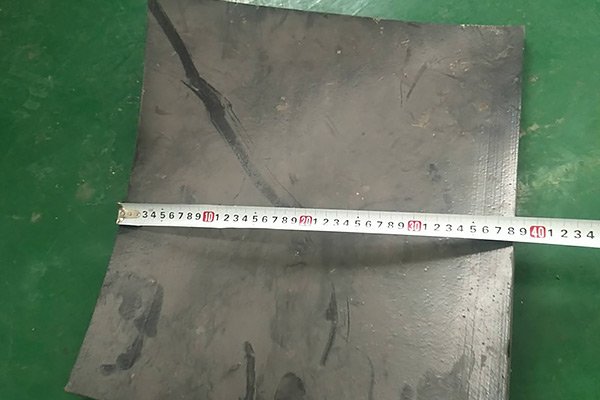

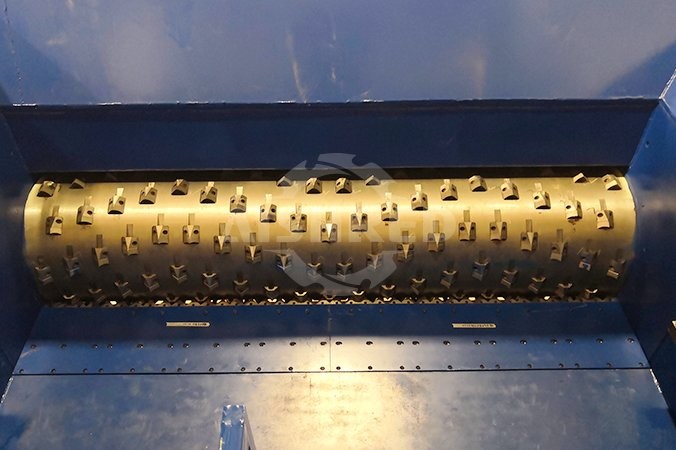

Single-shaft shredders are engineered for fine shredding to meet the materials size and consistency requirements of subsequent processes such as sorting, composting, anaerobic digestion, incineration, or pelletization. During operation, the rotors typically rotate at speeds ranging from 80 to 120 RPM, driving the cutting blades to finely shred the material. Single-shaft shredders are typically equipped with a classifier screen that allows to define the output size.

Single-shaft shredders have low tolerance for hard materials. When processing mixed materials, it is recommended to incorporate equipment such as trommel screens, magnetic separators, and eddy current separators into the production line to reduce the risk of hard foreign objects damaging the cutting blades.

GEP ECOTECH single-shaft shredders comprise two series with over 20 different models, designed to meet disposal requirements for various scales and materials. They have a production capacity ranging from a minimum of 0.5 tons per hour to a maximum of 50 tons per hour. Their robust and compact structure, coupled with top-tier durability and ease of maintenance, sets them apart in a highly competitive market.

GEP ECOTECH single-shaft shredder meets the recycling requirements of various materials and can process various pure and mixed materials such as plastics, rubber, tires, waste wood, wires and cables, non-ferrous metals, municipal solid waste, industrial waste, etc.