Batteries are currently the most widely used electrical energy storage devices. They are composed of casing materials, electrolytes, separator, and electrode materials (anode and cathode). Batteries are present in nearly every aspect of modern life, from electric vehicles like Tesla to smartphones, laptops, and other consumer electronics. Due to their widespread use and increasing consumption, waste batteries have become a significant environmental concern. As a result, many countries are now focusing on the proper recycling and recovery of spent batteries.

Common types of batteries include lead-acid batteries, nickel-cadmium (Ni-Cd) batteries, nickel-metal hydride (NiMH) batteries, lithium-ion batteries, zinc-carbon batteries, alkaline batteries, and primary lithium batteries. Recycling these batteries can recover valuable materials such as plastics, ferrous and non-ferrous metals, as well as critical metals like lead, lithium, cobalt, nickel, cadmium, and, in some cases, mercury.

The battery recycling process generally includes two major stages: size reduction (shredding) and material separation (sorting).

Waste Battery Shredding

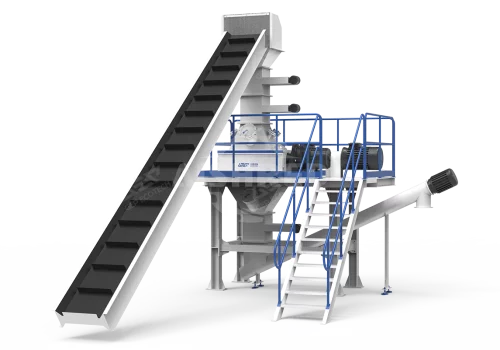

Waste batteries are fed—typically via conveyor systems or mechanical grabbers—into an industrial shredder, where they are broken down into smaller fragments. This process facilitates subsequent separation and material recovery.

It is important to note that certain types of batteries require pre-treatment before shredding. For example, lead-acid batteries contain liquid electrolytes that must be safely drained to prevent equipment corrosion and chemical hazards.

Shredding lithium-based batteries poses significant safety risks, including fire or explosion, due to the high reactivity of their components. Therefore, lithium battery shredding is typically performed in inert environments (e.g., nitrogen atmosphere or low-oxygen chambers) to mitigate the risk of thermal runaway.

Waste Battery Sorting

After shredding, the resulting mixed materials—such as electrode powder, casing fragments, and current collectors—must be separated to recover valuable resources. Depending on the battery chemistry, different separation methods are applied, including physical techniques (such as sieving, magnetic separation, gravity separation) and chemical processes (such as hydrometallurgy or pyrometallurgy). For example, in lead-acid battery recycling, gravity separation can be used to separate lead particles from plastics.

What GEP ECOTECH Does in the Battery Recycling Industry

GEP ECOTECH provides advanced material size reduction, separation, and conveying solutions for the recycling and solid waste management industries. In the field of battery recycling, we offer shredders engineered to handle the specific challenges of processing various battery types. We work closely with our customers to develop customized, efficient, and safe processing systems, continually optimizing the technology to meet evolving industry standards and safety requirements.