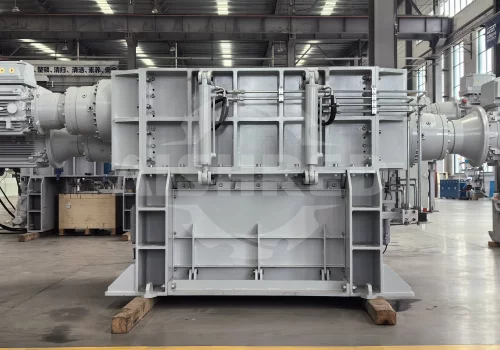

Waste tire, a common type of waste, exists in large quantities globally. With the increasing awareness of environmental protection and the emphasis on resource recycling, waste tire recycling has emerged as a highly promising industry, which has drawn significant attention from many countries and regions. So, how can we dispose of waste tire efficiently? Next, let me introduce the GF series four-shaft shredder of GEP ECOTECH to you.

Working Principle of the GF Series Four-Shaft Shredder

The GF series four-shaft shredder operates through the coordinated action of four sets of shear cutter rollers. The material is shredded by the tearing and shearing effects of the four sets of cutters. The size of the discharged material is controlled by screen. After the first-stage shredding, materials with a particle size smaller than the screen holes are discharged from the lower part of the box under the action of gravity and extrusion force. Materials with a particle size larger than the screen holes are guided back to the cutter box by the main and auxiliary cutters for a second-stage shredding, and this cycle continues until the materials are discharged through the screen holes.

Four-Shaft Shredder Technical Specifications

| Model | Capacity (t/h) | Discharge Size (mm) | Size (mm) |

| GF13 | 1-6 | 3200×2000×3000 | |

| GF15 | 2-10 | 20-150 | 4000×2000×3000 |

| GF18 | 3-15 | 4500×2200×3200 |

Currently, GEP ECOTECH offers the above three models of four-shaft shredders for your reference. Additionally, we can provide customized equipment according to the actual requirements of your project.

Advantages of GF Series Four-Shaft Shredder

- Efficient shredding: The four-shaft shredder uses four sets of shear cutter rollers to cooperate with each other, which provides stronger grasping and shearing capabilities for the material. Without the need for auxiliary feeding components, the shredding efficiency is higher.

- Controllable Particle Size: Compared with the double-shaft shredder, the four-shaft shredder is equipped with the screen. The size of the discharged material can be controlled by replacing the screen, meeting the requirements of different fields for the particle size of tire fragments.

- Durability and Stability: The cutters are made of imported high-alloy steel, and international well-known brand bearings are used. These components are resistant to wear and impact, have a long service life, and contribute to the continuous and stable operation of the equipment.

- Environmental - friendliness and Energy - saving: Imported reducers are adopted, featuring high transmission efficiency and large output torque. They can reduce the vibration generated during the shredding process, ensure the stable operation of the equipment, and reduce noise.

- GI Intelligent Control: The GI intelligent control system enables remote monitoring and fault early warning, greatly reducing maintenance and operation costs, improving the overall operation efficiency of the production line.

Therefore, the GF series four-shaft shredder plays a crucial role in waste tire disposal, enabling efficient tire shredding. If you are interested in our GF series four- shaft shredder and need to recycle and dispose of tires, please feel free to contact us.