Indonesia, like many other countries, has an abundance of coal resources, with numerous coal-fired power plants across the nation. However, the environmental impact of unsustainable coal mining, such as air pollution and greenhouse gas emissions, has become a major concern. In response, the Indonesian government has set ambitious goals to reduce coal dependence and explore cleaner energy alternatives, including the retrofit of coal power plants for biomass cofiring, to help achieve its carbon neutrality targets.

Many power companies in Indonesia have already taken proactive steps, developing retrofit plans and actively implementing biomass cofiring projects. For example, Indonesia Power replaced coal with biomass cofiring in 2023, reducing carbon dioxide emissions by 555,000 tons. Other power plants in Indonesia are also pushing forward with their biomass cofiring projects, and we have received numerous inquiries related to this transformation.

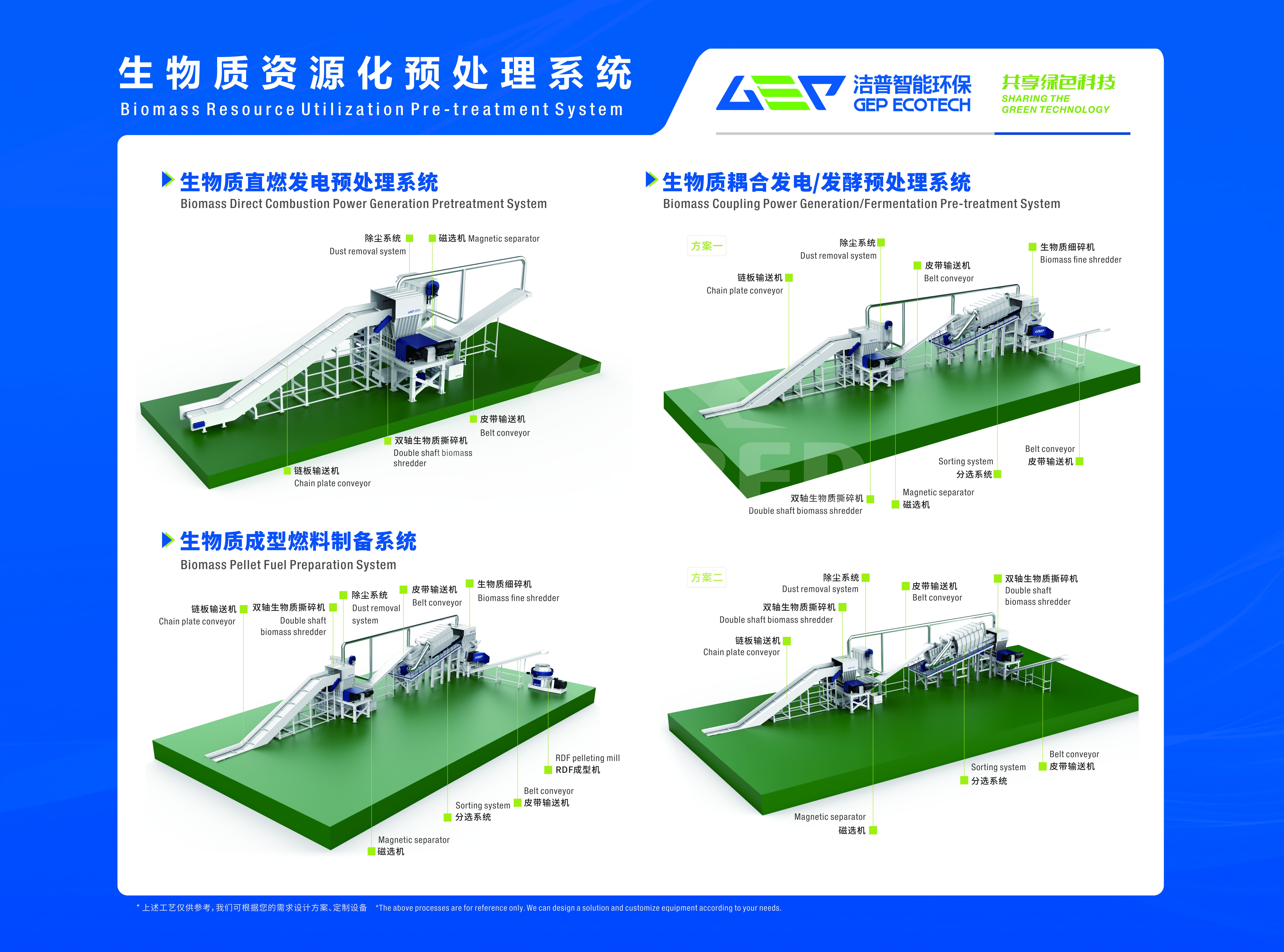

GEP ECOTECH is dedicated to helping coal power plants achieve their green transformation. We collaborate with numerous universities and research institutions and have implemented many biomass projects. With extensive industry knowledge and practical experience, we are capable of designing the most suitable solutions based on our clients’ unique needs—whether it’s direct cofiring, indirect cofiring, or parallel cofiring. Our team ensures that the transition to cleaner energy is seamless and effective for each customer.

At GEP ECOTECH, we understand that every power plant has its unique challenges and goals when it comes to transitioning to biomass cofiring. That's why we take a personalized approach, working closely with our clients to assess their specific needs and provide customized solutions. From system design and equipment selection to implementation and ongoing support, our team is there every step of the way.

Last month, my team hosted a client from Thailand, who primarily uses waste from sugarcane processing and other wood waste for cofiring in power plants. After touring our facility in Yuan County, Xinxiang City, the client shared their positive feedback: “I’ve visited over ten suppliers in China, but GEP ECOTECH’s factory truly stood out. Their top-notch facilities impressed me, and I’m eager to continue discussions on project details, including payment and delivery.”

If you're exploring ways to efficiently integrate biomass cofiring into your power plant operations in Indonesia, don’t hesitate to contact me.