The raw material water content entering a pyrolysis reactor is a critical factor for ensuring efficient and effective operation. Excess moisture can negatively impact the pyrolysis process, leading to higher energy consumption, reduced output quality, and potential operational issues. Here's a detailed explanation:

The maximum water content in the feedstock entering the pyrolysis reactor should typically be less than 15% by weight. Ideally, the moisture content should be below 5% for optimal performance.

Why Low Moisture is Important?

- Energy Efficiency: Water requires significant energy to evaporate, which reduces the thermal efficiency of the pyrolysis process.

- Output Quality: High moisture content can lead to the production of low-quality pyrolysis oil (with higher water content) and reduce the yield of usable products.

- Process Stability: Excess moisture can cause temperature fluctuations in the pyrolysis chamber, affecting the consistency of the process.

Impact of High Water Content

- Increased Energy Consumption: Evaporating water consumes energy that could otherwise be used for pyrolysis, increasing operational costs.

- Reduced Oil Yield: Water in the feedstock can dilute the pyrolysis oil, reducing its calorific value and marketability.

- Corrosion and Equipment Damage: Moisture can contribute to corrosion in the pyrolysis reactor and downstream equipment.

- Emissions: High moisture content can lead to the formation of steam and undesirable byproducts, increasing emissions.

Pre-treatment to Reduce Water Content

- Drying: Use mechanical dryers, rotary dryers, or thermal dryers to reduce moisture content before feeding the material into the pyrolysis chamber. Sun drying can also be used for certain materials, but it is less controllable.

- Sorting and Cleaning: Remove wet or high-moisture materials (e.g., food waste, wet paper) from the feedstock. Ensure the feedstock is free from external water sources (e.g., rainwater).

- Shredding and Size Reduction: Smaller, uniformly sized feedstock dries more efficiently and pyrolyzes more consistently.

Special Cases

- Biomass Feedstock: Biomass materials (e.g., wood, agricultural waste) often have higher natural moisture content. These materials typically require drying to below 10-15% moisture before pyrolysis.

- Plastic Feedstock: Plastics generally have very low inherent moisture content, but they may absorb water during storage. Ensure plastics are dry before processing.

- RDF (Refuse-Derived Fuel): RDF often contains moisture from organic materials. Pre-treatment (drying and sorting) is essential to reduce moisture to acceptable levels.

Monitoring and Control

Use moisture meters or sensors to measure the water content of the feedstock before it enters the pyrolysis chamber.

Implement automated feeding systems to ensure consistent feedstock quality and moisture levels.

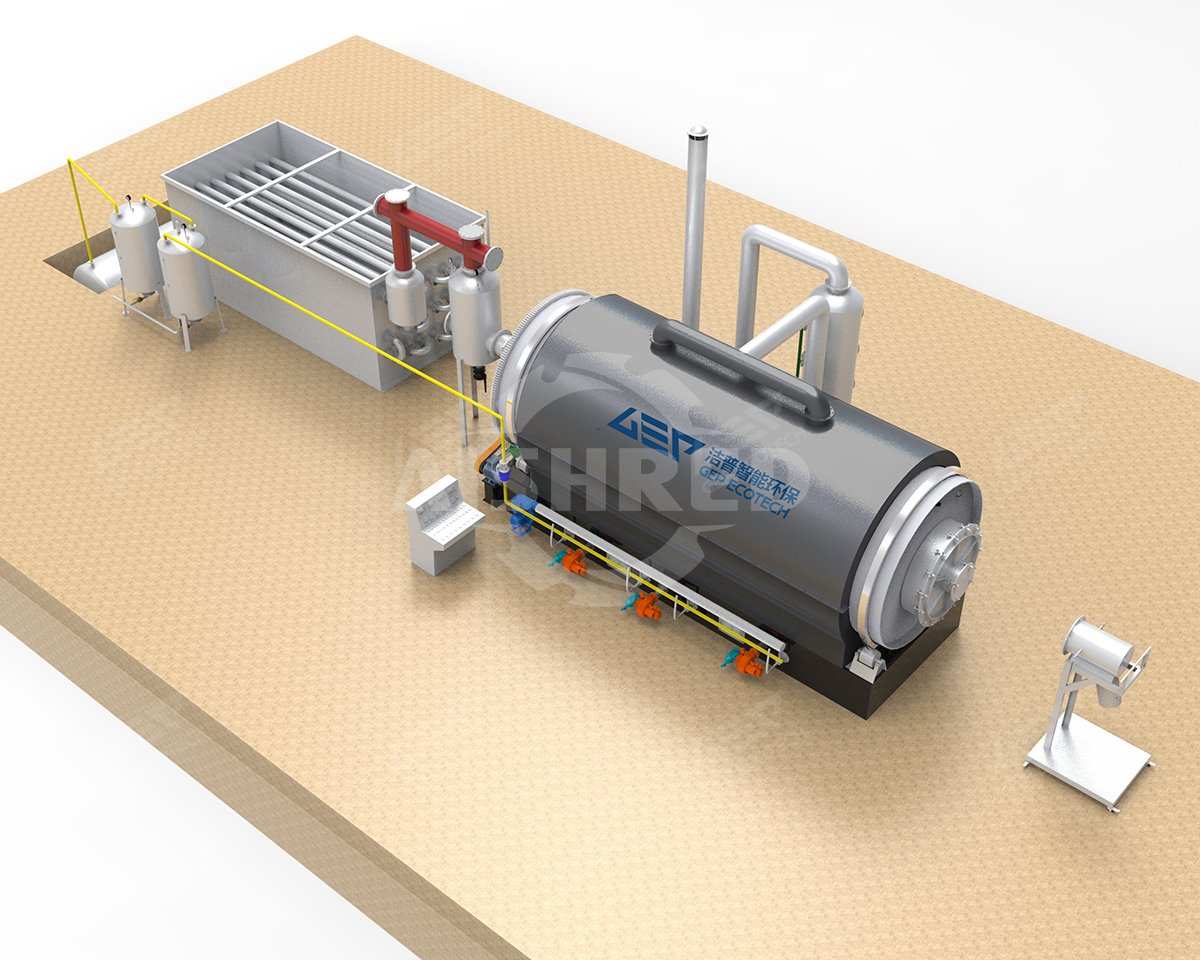

GEP ECOTECH has been focusing on tire and MSW pyrolysis for many years, and can provide you with corresponding solutions and quotations. If you have any related needs, please feel free to contact us at any time.