GEP ECOTECH's double-shaft shredders are versatile solutions for material reduction, meticulously designed for a range of applications. Our portfolio includes various models, each customizable with optional components tailored to specific requirements. Employing advanced technology and maintaining unwavering quality, GEP ECOTECH stands as a reliable choice for high-performance shredding solutions.

Send

Es una máquina muy competente q ayuda y facilita el trabajo además de su excelente rendimiento los resultados son muy satisfactorio.

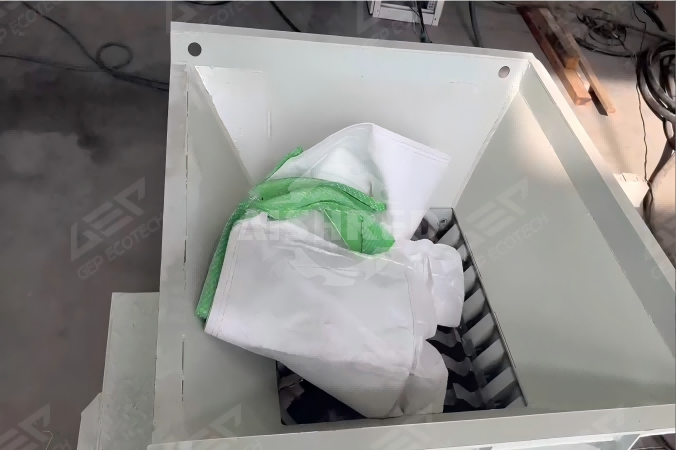

GEP ECOTECH's double-shaft shredders are expertly designed to process flexible and ductile materials, effectively serving purposes like destruction, volume reduction, or recycling. Operating at low speeds, these shredders deliver remarkable cutting force, capable of handling challenging materials while ensuring minimal noise and dust emissions.

The primary challenges for double-shaft shredders arise from complex operating conditions and fluctuating materials. These shredders are built to function in harsh environments where material flows can be variable and sometimes unpredictable. Inadequate torque might impede the completion of tasks, potentially leading to energy wastage due to continuous reversing. On the other hand, excessive torque, if not matched with appropriate machine performance, can cause severe mishaps, including the catastrophic failure of shafts.

Through innovative design concepts, selection of robust raw materials, meticulous manufacturing craftsmanship, and relentless enhancement of control software, GEP ECOTECH ensures that its double-shaft shredders deliver outstanding performance and reliability. These attributes make our shredders an optimal choice for processing intricate materials.

GEP ECOTECH double-shaft shredders are successfully operational in a variety of settings globally, including waste sorting centers, recycling plants, waste-to-energy facilities, cement factories, and composting sites. Their superior performance consistently exceeds industry standards, garnering worldwide recognition and trust from our clientele. This acclaim is a testament to their exceptional efficiency, durability, and state-of-the-art technology.