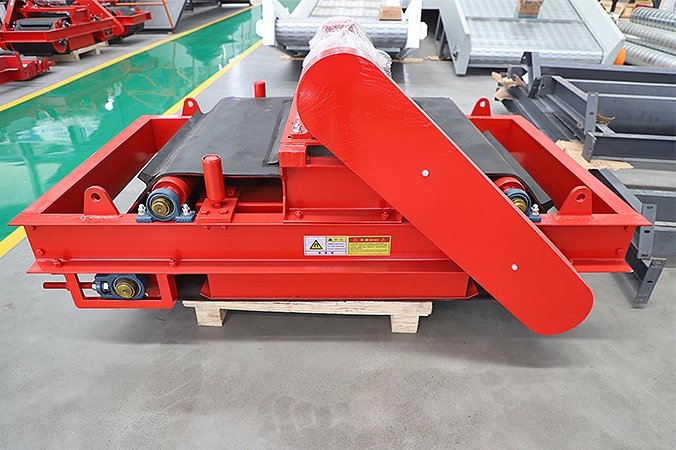

GEP ECOTECH's Magnetic Separators are high-performance devices designed to hang above or at the head of conveyor belts for continuous ferrous metal separation. They offer exceptional separation rates and come in two options: permanent magnet and electromagnetic, providing versatility for your specific needs. Discover GEP ECOTECH Metal separation solutions for improved efficiency and energy savings.

Send

Magnetic separators use the principle of magnetism to remove ferrous and paramagnetic metals from material flows. Their primary function is metal recovery, ensuring product purity, and safeguarding processing equipment from damage caused by impurities. They are equipped with permanent magnets or electromagnets to generate a magnetic field and include a conveyor belt for discharging the separated materials. Magnetic separators find wide applications in recycling, mining, and food processing industries.

The types of magnetic separators are diverse, including cross-belt magnetic separator, suspension magnetic separator, magnetic drum separator, magnetic rods and pullies, among others.

GEP ECOTECH offers a variety of configurations for magnetic separation equipment to meet the diverse needs of metal separation tasks. Our magnetic separators can be equipped with optional ultra-strong magnetic field intensity, ensuring efficient and reliable metal separation. Whether dealing with waste processing, metal recycling, or applications in mining and food processing, our magnetic separation technology delivers outstanding performance and solutions for your specific requirements.