Internationally, Refuse Derived Fuel (hereinafter referred to as "RDF") is regarded as a new way of waste harmless, recycling and reduction. It has been widely used in cement, power generation and other industries. It is green, environmentally friendly, high quality and low price Alternative fuels (SRF/RDF) are the new trend of the future. The preparation of waste-derived fuel RDF is not limited by site and scale. It is suitable for small and medium-sized waste treatment plants to be scattered and manufactured, and then collected for power generation, which is conducive to improving the scale and efficiency of waste-to-energy power generation.

Converting waste to waste-derived fuel (RDF) serves two purposes: it can reduce the amount of waste sent to landfills, thereby solving problems in the waste field, and it can supply large coal-fired power plants, waste incineration plants, cement plants Provides a large number of alternative fuel RDF.

GEP ECOTECH RDF&SRF Alternative Fuel Achievement Path

GEP ECOTECH has flexible solutions to help turn waste into fuel.

Recycling of Obsolete Waste

The most advanced foreign sorting technology and sorting equipment have been introduced, and the most targeted special equipment has been developed to realize series, modular and intelligent design, with strong adaptability and wide range of use. GEP ECOTECH has been able to achieve perfect disposal and resourceful reuse by sorting various end products such as humus (landscaping, alternative fuel), combustible materials (RDF), aggregates (backfill or cement kiln) and metals (recycling) according to local conditions.

Recycling of Bulky Waste

The bulky waste disposal system mainly consists of feeding system, coarse crushing system, iron removal system, fine crushing system and dust removal system, with high degree of automation and obvious effect of capacity and volume reduction.

The large piece of waste is shreded into small pieces of materials through the GEP ECOTECH special crusher, and then finely disposed of by magnetic separation and screening, the components with recycling value are recovered, and the remaining materials are sent to waste incineration power plant for incineration or cement plant, power plant and other cooperative disposal. Entering the bulky waste crushing line, the shreded materials get wood, metal and RDF, wood can be used for medium and high density plate processing and plate making, metal objects can be used for recycling iron and steel making, RDF can be used for power generation. After this series of process, the mattress, sofa and other large pieces of household waste decomposition and achieve 100% resource disposal. It can be reused and continue to shine.

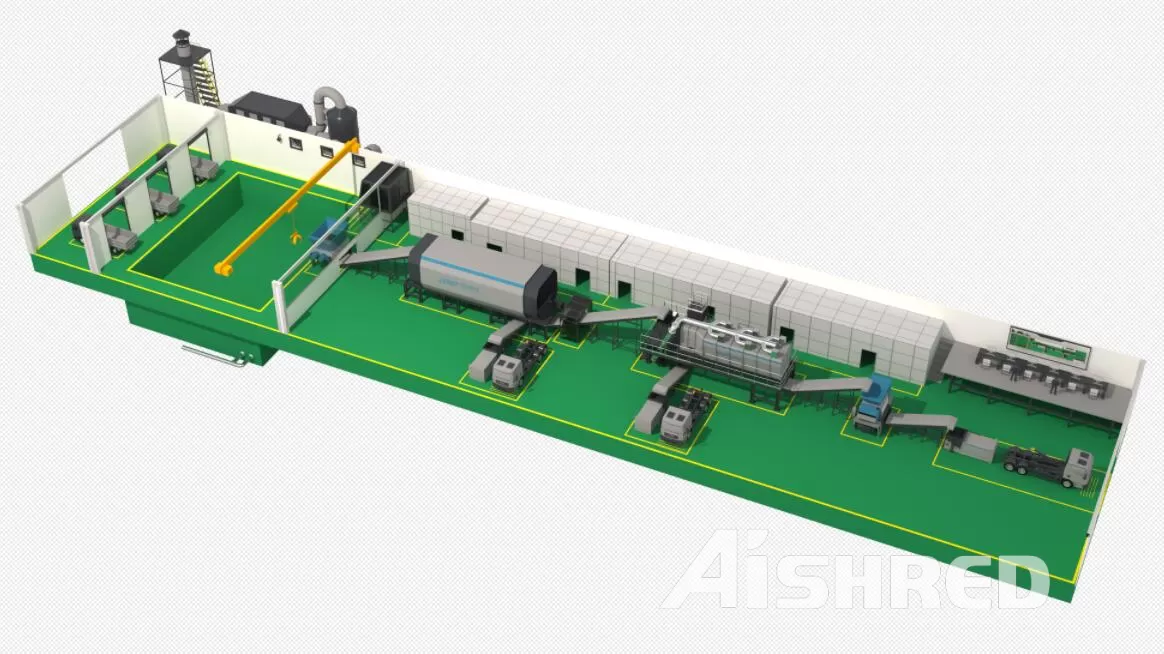

Energy from Domestic Waste

In order to solve the problem of high water content (low calorific value) of domestic waste, which leads to difficulties in incineration and excessive flue gas, GEP ECOTECH achieves efficient pretreatment of municipal domestic waste through technological innovation to meet the requirements of domestic waste preparation for RDF or higher incineration.

Process introduction: Municipal domestic waste is transported to the pre-treatment plant by waste transfer truck, and then through the process units of metering and weighing, primary crushing, bio-drying, magnetic separation, screening and gravity separation, the domestic waste is shreded and dried on the one hand, and sorted into metal, combustible and inert components on the other. The metals can be recycled, the combustibles are directly incinerated for power generation or made into RDF as an alternative fuel for cement plants, thermal power plants, coal-fired boilers, etc. The inert fuel is used as a raw material auxiliary for cement production or disposed of in landfills.