Why Choose Alternative Fuels for Cement Kilns?

- Fossil fuels (coal) are limited and non-renewable resources

- Using alternative fuels reduces carbon dioxide emissions

- Alternative fuels lower the processing cost of cement production

- There is an increasing need to manage industrial and municipal waste (landfilling is not a sustainable solution)

- Compared to other industrial consumers, cement kilns are capable of handling a larger volume of difficult-to-treat waste

GEP ECOTECH's Two Alternative Fuels Production Solutions

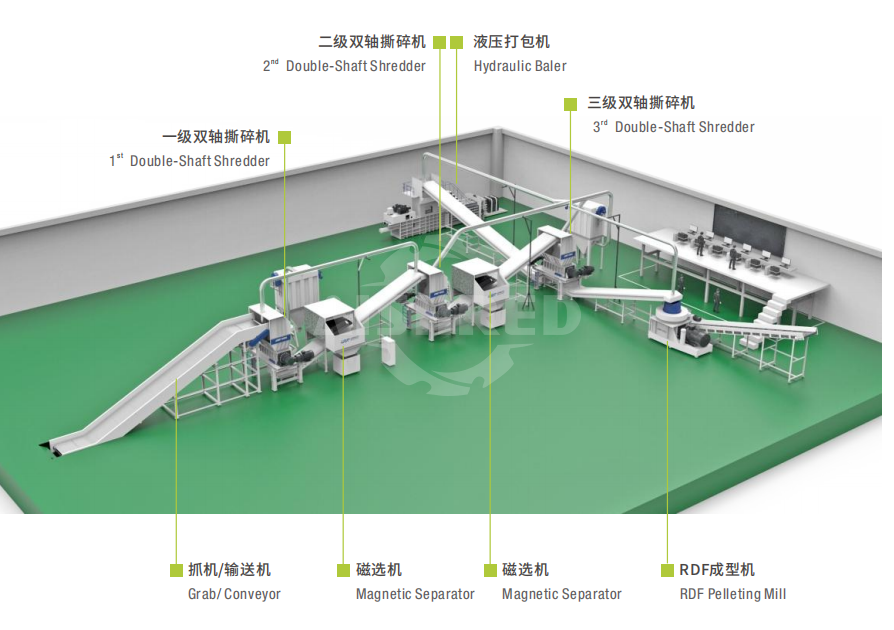

Solution 1: Three-Stage Double-Shaft Shredder

Advantages:

- The entire system—covering shredding, conveying, sorting, and shaping—is modular in design, allowing for a more compact and rational layout.

- Automated operation significantly reduces manual labor, improves production efficiency, and lowers operating costs

- The resulting RDF fuel rods are stable in composition and form, featuring high density, high calorific value, and high quality, with a stable market demand.

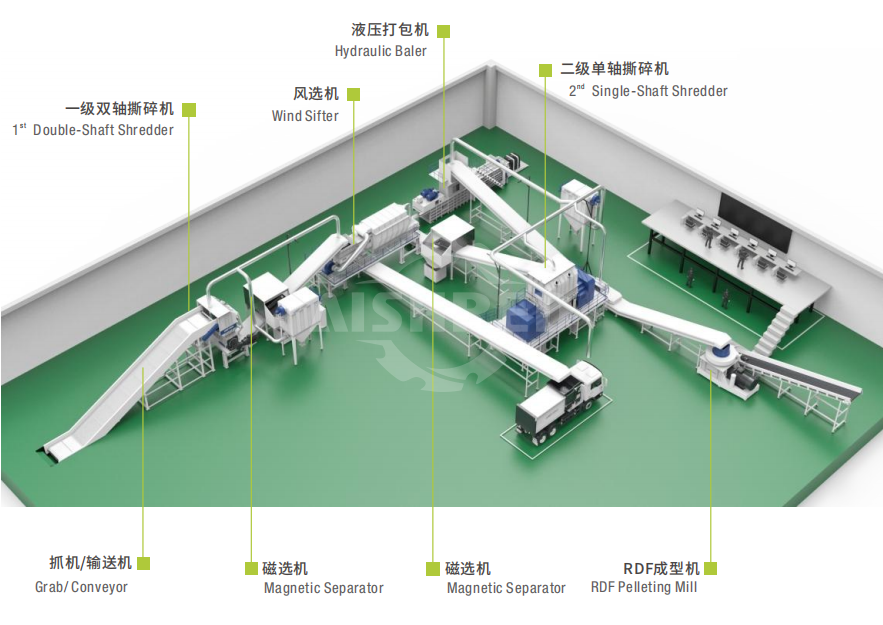

Solution 2: Double-Shaft Shredder + Wind Sifter + Single-Shaft Shredder

Advantages:

- Fully utilizes the twin-shaft shredder's powerful processing capacity, excellent shredding effect, and broad material adaptability.

- Achieves lower operational costs under the same output conditions, with notable energy savings and easier, low-cost maintenance.

- Equipped with the GI intelligent system, which monitors current, temperature, and load in real time, automatically adjusting rotation speed and feed rate to optimize operational efficiency.

GEP helps cement kilns turn waste into energy, cut emissions, and reduce costs — driving sustainable development.