Solid alternative fuel RDF/SRF is a solid form of fuel made from industrial solid waste through various processes. By reducing the water content of industrial waste and increasing the calorific value of the product, it replaces traditional energy sources (coal) and reduces pollutant emissions, thus realizing "turning waste into treasure".

Energy Structure and Prospects

From the perspective of energy structure, alternative fuels (SRF/RDF), as a renewable energy source with broad prospects, are processed from solid wastes, with combustion efficiencies similar to those of fossil fuels, but with low carbon emissions, and are generally utilized in existing thermal power plants, cogeneration plants, and cement kilns to carry out coupled power generation/blending power generation/mixing power generation/co-disposal in cement kilns with RDF/SRF, which saves costs for enterprises and contributes to the environmental protection.

The substitution relationship between fossil fuels and alternative fuels (SRF/RDF) is:

- 1.4 tons of alternative fuel = 1 ton of coal

- 1.7 tons of alternative fuel = 1 ton of petroleum coke

- 2 tons of alternative fuel = 1 ton of fuel oil

The cement manufacturing industry is considered to be one of the largest energy-consuming industries in the world. In addition, it faces challenges from both economic and environmental perspectives. Therefore, solid waste as an alternative fuel has a lot of potential in this sector. In order to meet the energy requirement of 120 kWh/ton, cement plants use 12-15% of the total global industrial energy. In terms of CO2 emissions, 5-7% of global CO2 emissions are generated by the cement industry. However, several studies have shown that these figures have fallen by about 5 per cent globally in recent years as a result of improvements in energy efficiency and the use of alternative fuels.

RDF Application Fields

- Power Generation: Economical mixing of RDF with coal in thermal power plants and the development of RDF combustion boilers.

- District Heating Project: Specialized RDF combustion boilers for efficient RDF heat supply.

- Co-disposal in Cement Kilns: Utilizing RDF combustion ash as a raw material in cement manufacturing.

- Drying Process: Burning RDF in a special boiler for thermal applications like drying and deodorization.

- Small and Medium-sized Public Places: Applications in heated facilities such as swimming pools, gyms, hospitals, and public baths.

- Application as Carbide: Pyrolyzing RDF for combustible gas used in heating, with resulting carbide utilized as a reducing agent in ironmaking.

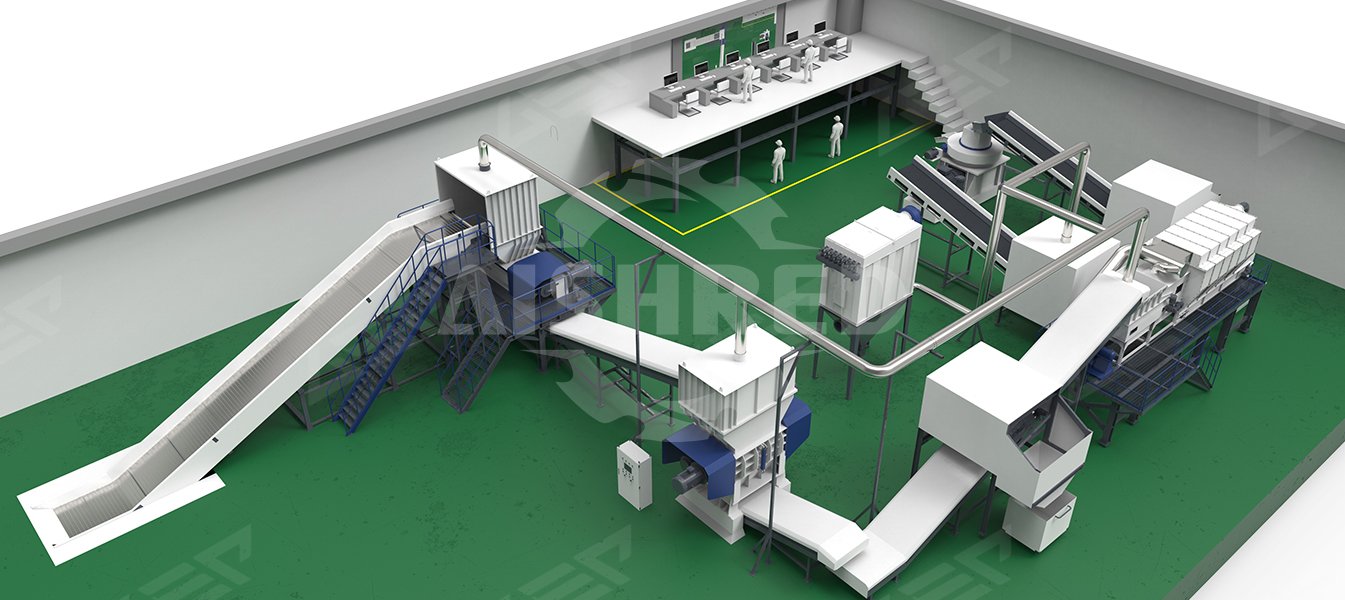

GEP ECOTECH has introduced advanced technology and concepts, combined with thousands of successful application cases, to develop a distinctive alternative fuel (SRF/RDF) pretreatment system, suitable for the recycling and treatment of various waste textiles and high calorific value industrial solid waste. Based on the actual situation and needs of users, it provides customized solid waste treatment solutions.