Cement kilns, with their high-temperature combustion environment (>1450 °C in the burning zone), long residence time (several seconds in the main flame, >20 minutes overall), and stable operating conditions, provide a technically feasible platform for the co-processing of municipal solid waste (MSW), sewage sludge, and other alternative fuels. For small and medium-sized cement plants, this approach offers a reference pathway to reduce landfilling, recover energy, and improve environmental performance.

In practice, the process generally consists of two major streams:

- Preparation of Refuse-Derived Fuel (RDF) from MSW, involving shredding, sorting, drying, and particle size reduction (typically 30–80 mm) to meet kiln feeding requirements.

- Dewatering and conditioning of sewage sludge, where moisture content is reduced (generally to below 40 % by weight) and the material is prepared for stable and safe kiln feeding.

Both RDF and sludge can be introduced into the kiln through dedicated feeding systems. Properly designed systems ensure stable combustion, achieve thermal substitution rates typically in the range of 15–30 %, and maintain compliance with environmental standards.

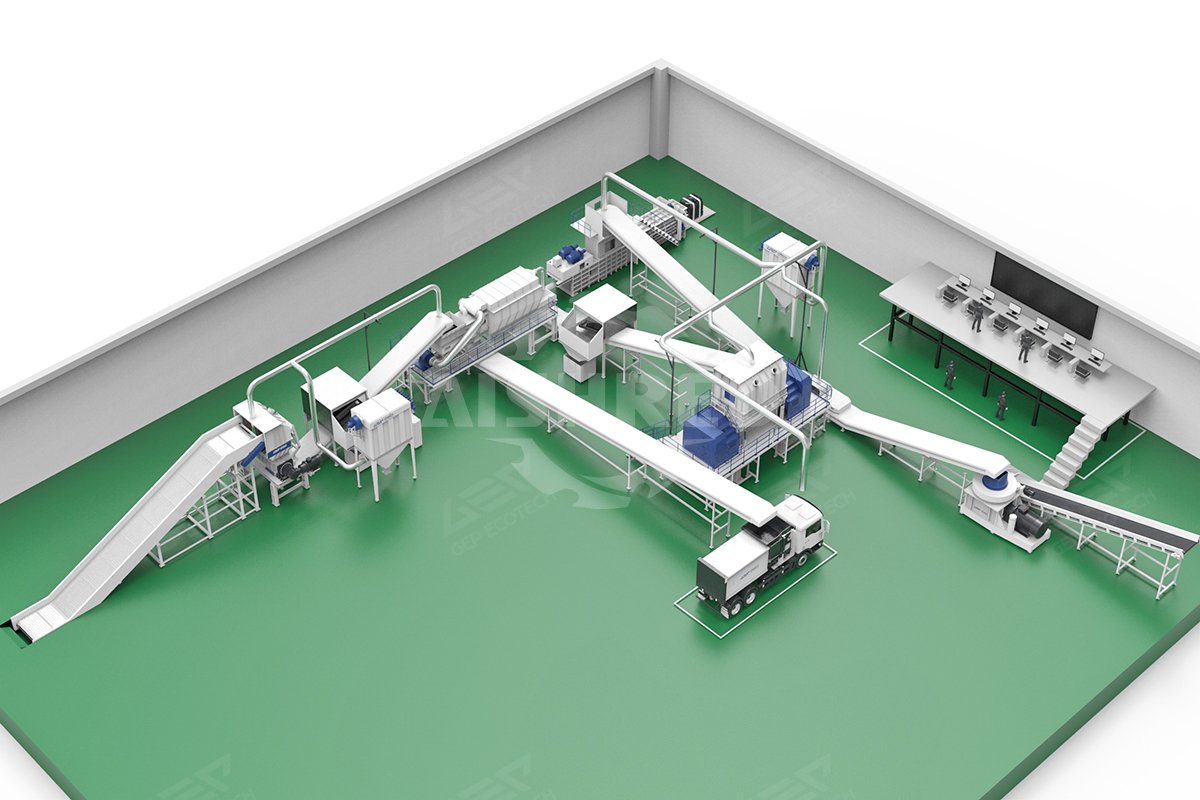

RDF Preparation Process

RDF production is designed to convert mixed municipal waste into a more uniform and higher-calorific value fuel suitable for cement kilns. The process generally includes the following steps:

- Waste reception and pre-shredding – Collected MSW is unloaded and subjected to coarse shredding, reducing bulky materials to sizes of <300 mm.

- Screening and sorting – Magnetic separation, air classification, and automated/manual sorting remove inerts and recyclables. Non-combustible fractions (e.g., stones, glass, metals) are reduced to <10 % of the input stream.

- Secondary shredding – The combustible fraction is further reduced to 30–80 mm particle size to ensure smooth feeding and complete combustion.

- Moisture control – RDF moisture is generally maintained below 20 % to prevent blockages and maintain stable combustion.

- Refinement and homogenization – The material is blended to achieve stable quality, with calorific values typically ranging from 12–18 MJ/kg (depending on waste composition).

- Compaction and transportation – Processed RDF may be baled or pelletized to improve handling efficiency, with typical bale density in the range of 0.6–0.8 t/m³.

By following these steps, RDF can replace 10–20 % of fossil fuels in cement kilns while maintaining process stability.

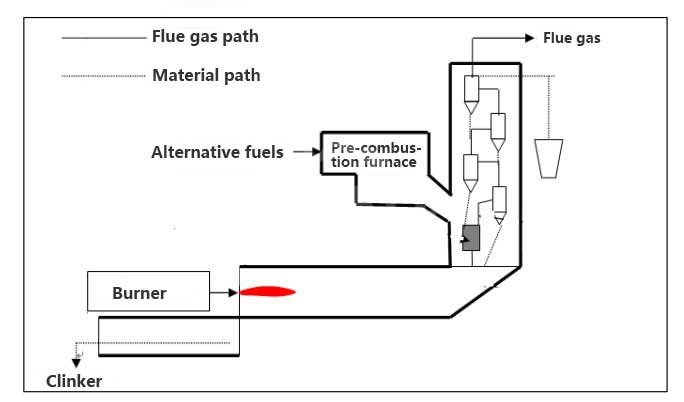

Feeding into the Cement Kiln

Different waste streams are introduced into the cement kiln through dedicated feeding systems, each designed to ensure stable combustion, accurate dosing, and safe operation. The main approaches include:

- Sewage Sludge Feeding

Dewatered sludge (moisture content typically <40 %) is discharged from storage silos and conveyed into a positive-pressure feeding pump. It is transported via pipelines directly to the pre-calciner. Feeding rates commonly range from 5–20 t/h, depending on kiln capacity. The sludge flow is precisely regulated by pump speed adjustment. - RDF Feeding

RDF is discharged from storage through twin-screw feeders and transferred by tubular belt conveyors to a kiln head buffer silo (typically 100–300 m³ for medium plants). Inside the silo, mixing devices homogenize the material before it is metered by a sealed dosing unit. Controlled feed is introduced via multi-channel burners, replacing 10–20 % of coal in most configurations. - Screened Residue Feeding

Screened fine fraction (<30 mm) is fed into a plate-type feeder, then measured by a sealed dosing device. It is transported by tubular belt conveyors to the kiln tail pre-calciner, contributing 3–8 % of the total thermal substitution. - Tire-Derived Fuel (TDF) Feeding

Waste tires can be processed into chips (approx. 50 × 50 mm) and introduced via dedicated feeding systems. Alternatively, whole tires may be fed directly into the mid-kiln or kiln inlet. The high combustion temperature and long residence time ensure complete burnout, allowing TDF to provide a consistent high-calorific fuel source (20–30 MJ/kg).

Combustion and Flue Gas Cleaning System

Within the kiln system, RDF, sewage sludge, residues, and TDF are combusted under extremely high temperatures (>850 °C in the calciner, >1450 °C in the main kiln) and long residence times (>20 minutes total). This ensures complete destruction of organic pollutants, pathogens, and hazardous components while simultaneously providing the thermal energy needed for clinker production.

To guarantee emission compliance, a comprehensive flue gas cleaning system is applied. Typical configurations include:

- Cyclone pre-separators – >90 % removal for particles >20 µm.

- Bag filters or ESPs – capturing fine dust, typically achieving outlet dust concentrations below 30 mg/Nm³.

- Deacidification and adsorption – lime injection for SO₂ and activated carbon for dioxins/heavy metals, with SO₂ removal efficiencies >80 %.

- NOx reduction – staged combustion or SNCR, reducing NOx to <400 mg/Nm³.

Odor Control System

Odor control is implemented throughout the process to ensure safe and acceptable working and living environments. Measures typically include:

- RDF Pre-treatment Facilities

- Workshops fully enclosed and operated under negative pressure (–50 to –150 Pa).

- Semi-enclosed unloading zones with localized ventilation.

- High-pressure plant-based spraying (10,000–30,000 m³/h per unit) and photocatalytic devices for shredding and compaction areas.

- Biological scrubbers at intensive odor points such as compaction lines.

- Cement Plant Storage Areas

- Sludge, RDF, and residue silos built with gas-tight structures.

- Air curtain doors at entrances (airflow velocity ≥10 m/s).

- Odor treatment systems (TiO₂ photocatalysis + spraying) installed for extracted air.

- Sealed transport: sludge by pipelines, RDF/residues by tubular belt conveyors, all under negative pressure.

Alternative Fuel Systems by GEP ECOTECH

GEP ECOTECH provides flexible and customized alternative fuel systems that can be adapted to the specific requirements of cement plants of different scales. The systems are designed to process and deliver RDF, SRF, and TDF (tire-derived fuel) safely and efficiently.

- Applicable waste streams: MSW, industrial residues, sewage sludge, biomass, and waste tires.

- Core processing units: shredders, magnetic separators, air classifiers, screens, pelletizing/baling systems, sealed conveyors, and intelligent monitoring.

- Key features:

- Modular design, with capacity options from 50–500 t/d, suitable for small to medium-sized kilns.

- Particle size control: RDF (20–80 mm), SRF (10–30 mm), TDF (50 × 50 mm chips or whole tires).

- Flexible integration with kiln main burner, calciner, or kiln inlet, ensuring stable combustion and high substitution rates.

By adopting GEP ECOTECH’s solutions, cement plants can significantly reduce fossil fuel dependency, improve energy efficiency, and cut direct CO₂ emissions by 20–40 kg per ton of cement, depending on substitution rates.