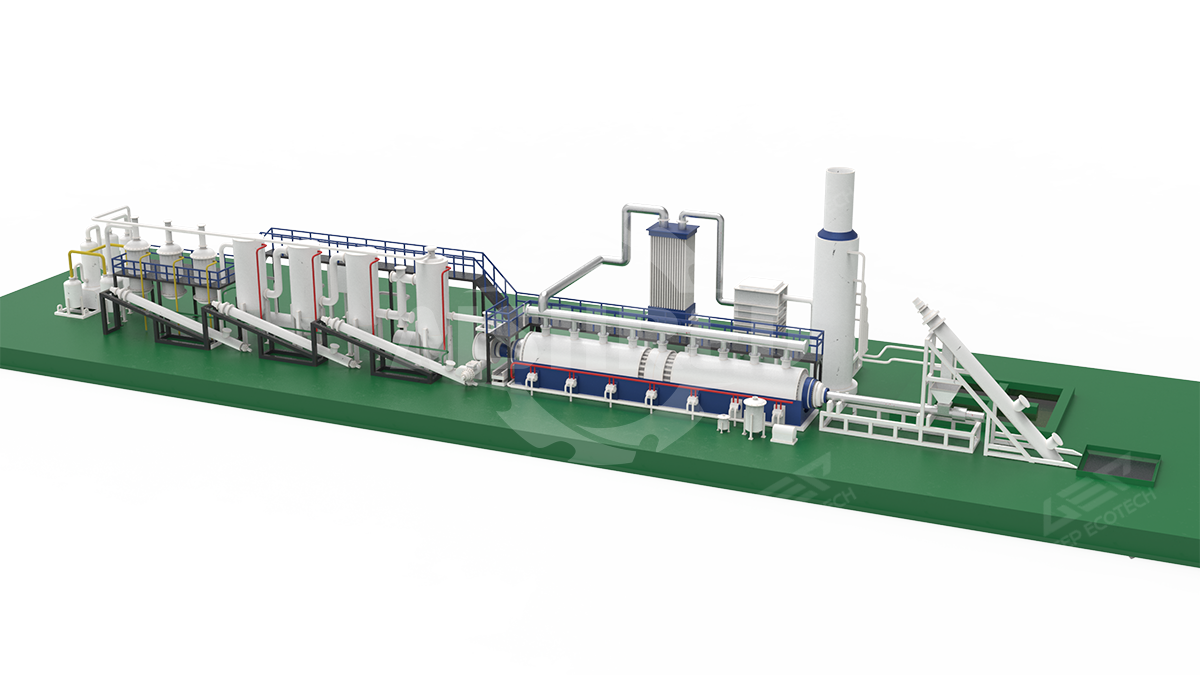

GEP ECOTECH offers a state-of-the-art continuous waste tire pyrolysis system designed to convert scrap tires into valuable products such as pyrolysis oil, carbon black, steel wire, and syngas, with near-zero emissions and continuous, automated operation. This technology is ideal for investors seeking sustainable and profitable solutions for waste rubber recycling.

Key Process Overview

- Feeding: Rubber shreds are fed into a sealed extruder and conveyed to the pyrolysis reactor.

- Pyrolysis Reaction: Occurs at 390–430°C under micro-negative pressure in an oxygen-deficient chamber.

- Oil-Gas Separation: Oil vapors are condensed into liquid fuel; non-condensable gas is purified.

- Fuel Recycling: Cleaned syngas is reused as a heating source for the pyrolysis reactor.

- Solid Separation: Steel and carbon black are magnetically and thermally separated.

- Emission Control: Flue gases are treated to meet environmental regulations.

- Closed-loop Cooling: Efficient water system ensures minimal water and energy use.

- Centralized Control: Smart PLC system provides 24/7 monitoring and fault alerts.

Technical Parameters

| Output/Product | Typical Yield (per ton of tires) |

|---|---|

| Pyrolysis Oil | 43%–48% |

| Carbon Black | 32%–36% |

| Combustible Gas | 8%–12% |

| Steel Wire | 11%–13% |

| Pyrolysis Efficiency | >99% |

| Heat Recovery Rate | >90% |

Operating Cost Analysis

Operating costs for GEP ECOTECH’s continuous pyrolysis plant are broken down per ton of waste tire processed. The following figures are based on a mature 20,000–60,000 ton/year configuration:

| Cost Item | Unit Cost (CNY) | Approx. USD |

|---|---|---|

| Electricity | ¥70 / ton | ~$10 |

| Water Consumption | ¥2.33 / ton | <$0.50 |

| Tire Feedstock (raw mat.) | ¥600 / ton | ~$83 |

| Chemical Additives | ¥23 / ton | ~$3.20 |

| Equipment Depreciation | ¥110 / ton | ~$15 |

| Labor & Maintenance | ¥32 / ton | ~$4.50 |

| Total Operating Cost | ¥837.33 / ton | ~$116 / ton |

Note: Values may vary slightly by region, feedstock form (whole vs. shredded tires), and labor costs.

Energy and Resource Efficiency

GEP ECOTECH’s plant design focuses on maximum resource recovery and minimum external energy input:

1. Energy Consumption

| Metric | Value |

|---|---|

| Integrated energy use (per ton tire) | ~27.9 kgce (kg coal eq.) |

| Industry baseline (GB standard) | 36.87 kgce / ton |

| Energy savings | ~24% below benchmark |

This includes:

- 14.4 kgce for pyrolysis processing

- Additional energy for auxiliary systems

2. Reuse of Syngas

- ~8–12% of tire mass is converted to non-condensable gas.

- After purification, this gas is entirely reused for heating the pyrolysis reactor.

- Zero external fuel required during normal operation.

3. Resource Output Per 60,000 Tons/Year Plant

| Product | Annual Output | Resource Efficiency |

|---|---|---|

| Pyrolysis Oil | ~45,400 tons | Used as boiler fuel or refined to diesel |

| Carbon Black | ~20,500 tons | Replaces fossil-based carbon black (saves ~37,800 tons coal tar) |

| Steel Wire | ~6,600 tons | Fully recyclable as scrap metal |

| Syngas (reused) | 100% internal use | Saves ~5,400 tons fuel oil/year (~7,710 tce) |

| Heat Recovered | >90% | Through smoke gas recycling and insulation |

4. Environmental Impact Reduction

- CO₂ Emissions Reduction: ~58,300 tons/year for a 60,000 t/y plant

- Air Emissions: Meet or exceed GB16297-1996 and DB37/2376-2013 standards

- Zero Liquid Waste: No wastewater discharged

- Solid Residue Use: All outputs (oil, carbon, gas, steel) are resold or reused

Join the green revolution by turning tire waste into valuable resources. GEP ECOTECH is your reliable partner for building a clean, profitable recycling plant with guaranteed performance and support.