The usual construction waste treatment method is mainly landfill, and the resource utilization rate is about 40%. The main components of urban construction waste include muck, concrete blocks, brick and stone tiles, sand slurry, asphalt, metal, plastic, textiles, wood, foam, glass, etc. most of them can be used as new engineering construction raw materials after treatment. After treatment, concrete blocks can be made into recycled aggregate. After treatment, 100 tons of construction waste can be turned into 88 tons of recycled aggregate, which not only solves the problem of enclosing the city with garbage, at the same time, it also protects land resources and creates economic benefits.

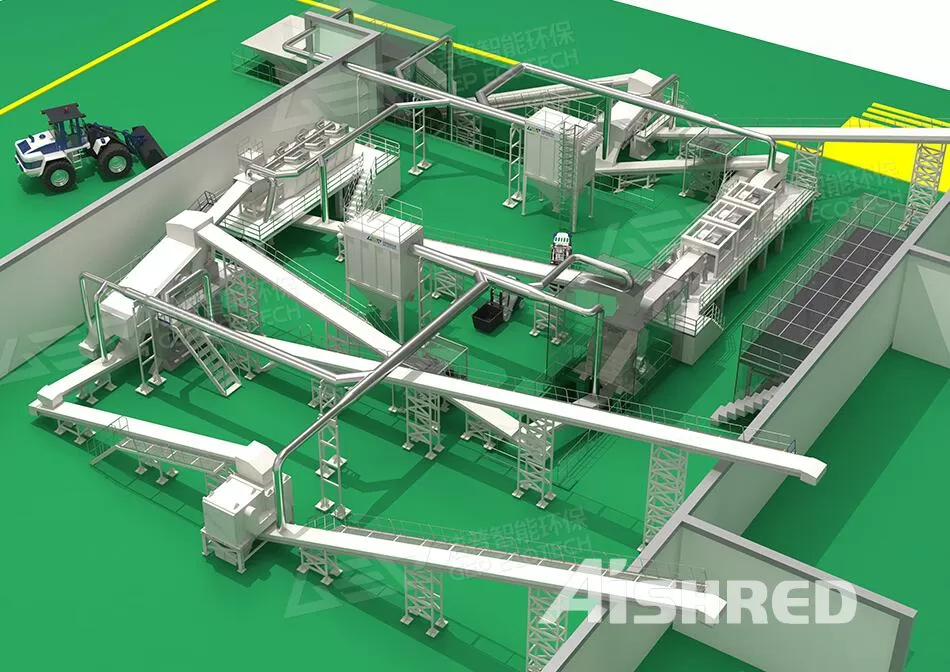

How to deal with the construction waste? It requires a series of equipment to realize the resource treatment of construction waste, that is the construction waste treatment production line. Its work flow is that the construction waste is transported to the crushing equipment through the feeding equipment. After one or two-stage crushing, the construction waste can be screened into finished aggregates with common particle sizes. In this process, other equipment, such as air separation equipment and water flotation equipment, will be used to separate the wood, plastic and other sundries in the construction waste. These separated materials can also be used for resource utilization or incineration for power generation, and the qualified aggregates can be sold.

GEP ECOTECH is a manufacturer focusing on solid waste treatment, independently developing and producing core equipment. Construction waste treatment is one of our main businesses. If you want to enter the huge market of construction waste treatment and want to know more about construction waste treatment equipment, please contact us.