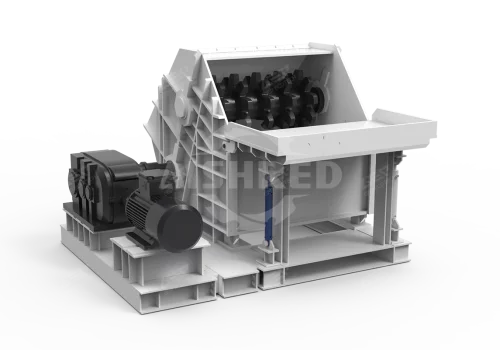

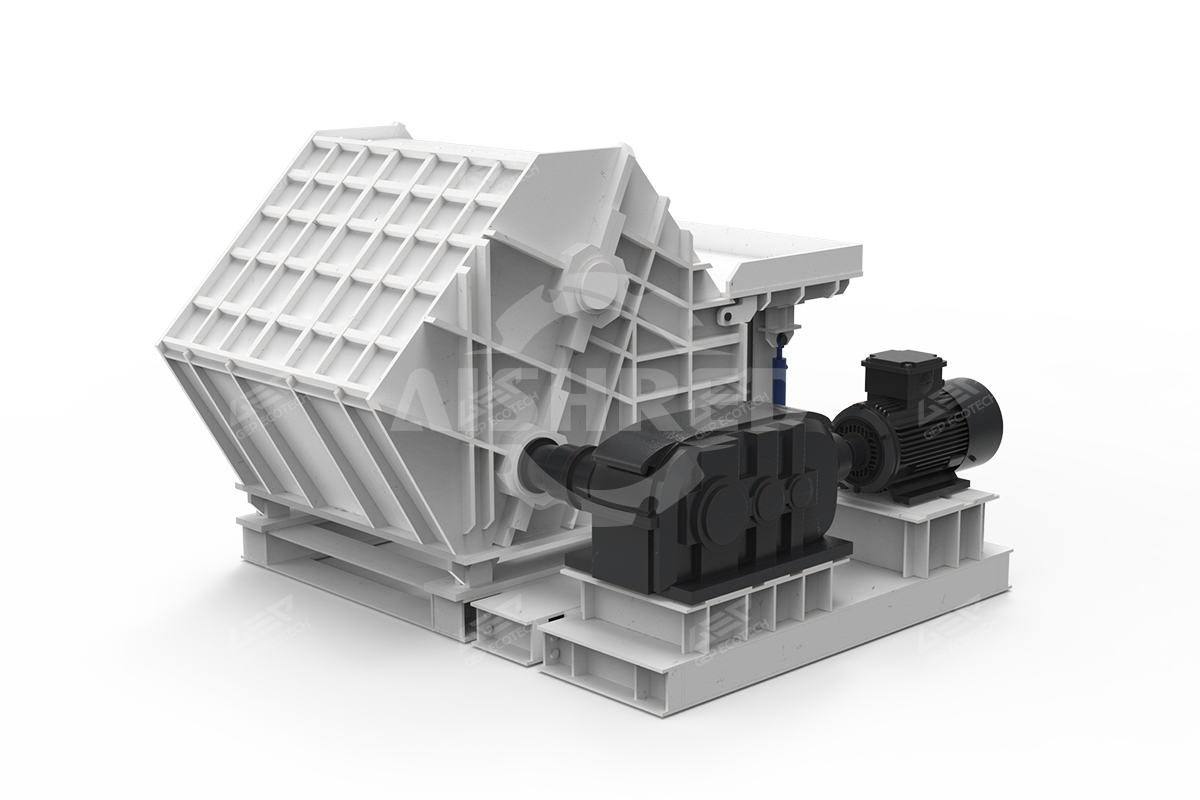

Today, we are introducing the metal debaler, also called metal bales opener/breaker, a machine widely used in the metal recycling industry. This compact, robust, and powerful equipment delivers excellent performance in improving efficiency while significantly reducing labor and time costs.

One of the key challenges in metal recycling is maximizing your input-output ratio. Typically, you don't want a production line that is either too powerful or too small. In many of GEP Ecotech's case studies, our customers have successfully addressed these challenges with this equipment.

Problems Arisen from Metal Bales Recycling

Similar to traditional agricultural baling processes (e.g., straw or stalks), baling materials helps save a considerable amount on transportation costs. However, it also introduces the challenge of unbaling the materials before moving on to the next stage of processing. In metal recycling, if you are unable to efficiently unbale the materials, you may face several issues:

- Over-investing in larger shredders: This would significantly increase both equipment and operational costs.

- Inability to effectively remove debris: Large, solid items that should not enter the shredding and sorting line may cause operational disruptions (while it's impossible to eliminate all such issues, this is an inherent challenge in the industry).

- Increased wear and tear on equipment: Over time, the prolonged operation of machinery without effective unbaling can cause excessive wear, raising operating costs to the point where further investment and expansion may no longer be viable.

Those in the industry know that metal recycling and disposal often require substantial investment, with both potential benefits and risks. The key is to strike a balance between these two factors to maximize returns while minimizing risk.

Advantages of a Metal Debaler

A metal debaler, typically powered by an electric or hydraulic motor, uses rotating blades or a mechanical breaking system made from durable materials (usually hardened steel) to cut or split bales. This process makes it easier to access the materials inside for further processing, particularly with larger bales.

Compared to traditional manual methods, the metal debaler offers several advantages:

- Increased Work Efficiency: The metal bale opener significantly speeds up the unpacking process through automation. Traditional manual methods are time-consuming and labor-intensive, often limited by worker fatigue. In contrast, the automated operation of the metal bale opener enhances productivity and reduces manual labor time.

- Reduced Labor Costs: The metal bale opener performs the dismantling automatically, minimizing reliance on manual labor. This reduction in labor requirements allows businesses to allocate human resources to more value-added tasks, optimizing workforce efficiency and reducing labor costs.

- Enhanced Safety: Manual unpacking involves handling sharp metal edges, which can lead to injury. The metal bale opener is designed with safety features that reduce direct contact between workers and hazardous materials, thereby enhancing workplace safety.

- Reduced Labor Intensity: Dismantling metal packaging manually requires significant physical effort, and the repetitive nature of the task can lead to fatigue. The metal bale opener's automated operation significantly reduces labor intensity, improving employee comfort and job satisfaction.

- Minimized Human Error: Manual unpacking is prone to errors due to variations in operator experience and skill. Automation with a metal bale opener minimizes human intervention, ensuring more consistent and standardized results.

- Ideal for Mass Production: Companies dealing with large volumes of metal packaging can benefit from the continuous, stable operation of a metal bale opener. This makes it especially suitable for high-volume production environments such as metal scrap recycling or raw material processing on production lines.

Overall, metal debalers offer substantial benefits in terms of improving work efficiency, enhancing safety, reducing labor costs, and boosting resource recovery. These advantages make them indispensable in modern production environments, particularly in the metal recycling industry.

GEP ECOTECH is not only capable of providing customized solutions but also optimizing processes and upgrading technologies to address the unique challenges at your site.