A new metal crushing and sorting line has begun trial operation in central China. This advanced production line integrates various high-efficiency equipment, including a metal shredder, magnetic separator, eddy current separator, air classifier, dust removal system, and other components, capable of processing around 15 tons of metal waste per hour. The line is designed to transform complex scrap metal into high-quality secondary raw materials through a multi-step process.

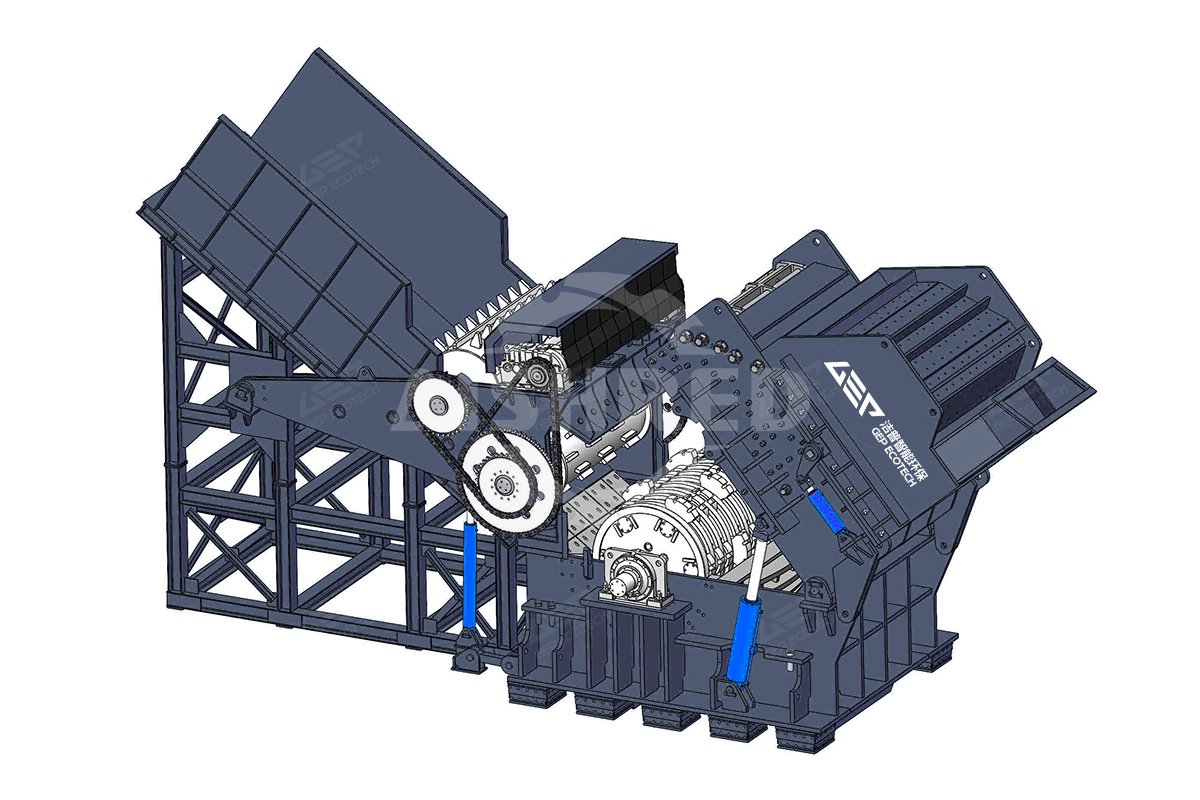

The core of this line is the metal crusher, which is responsible for breaking large scrap metal into smaller, recyclable pieces. Following crushing, the magnetic separator and eddy current separator efficiently separate ferrous and non-ferrous metals, ensuring accurate material classification. The air classifier is used to remove lighter impurities, ensuring the purity of the final product. Meanwhile, the dust removal system significantly reduces dust emissions, meeting environmental standards.

The processed product consists of clean, small metal pieces of high quality, ready to be packed and transported to smelting plants for the production of new metal products. This process not only promotes resource recycling but also provides a sustainable development path for related industries.

Learn more about our metal crushing and sorting solutions: https://www.aishred.com/application/scrap-metal-processing.html