Scrap Aluminum Shredder is a kind of shredding equipment used to process scrap aluminum, which is mainly used for the shredding and sorting operation of machined aluminum, raw aluminum, aluminum alloy and broken aluminum. With advanced technology, large processing range and high production efficiency, the production line can fully separate iron, aluminum and plastic, and the purity can reach more than 99%, and the production process is noiseless and non-polluting, which is the mainstream equipment for scrap aluminum recycling at present.

Process Flow

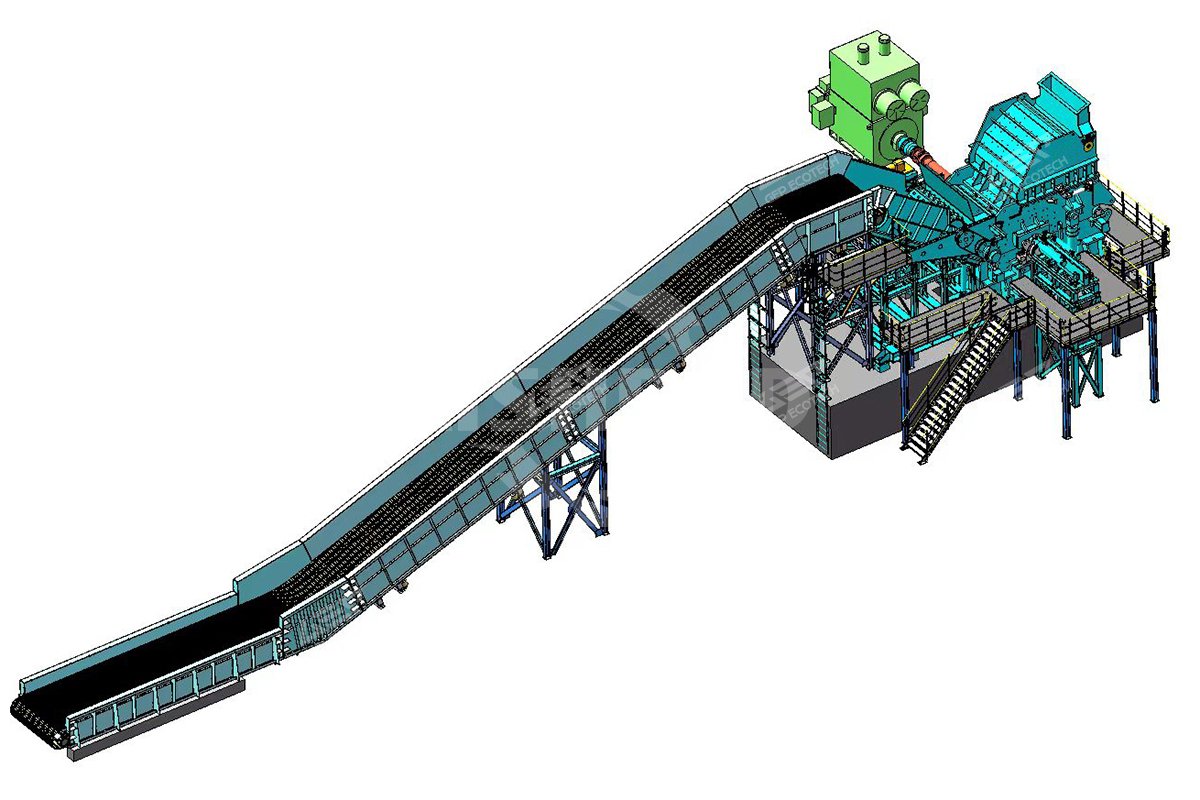

Scrap aluminum shredding and sorting equipment consists of scrap aluminum shredder, magnetic separator, trommel screen, eddy current sorter and dust collector. The material is sent into the aluminum shredder for fine shredding through the conveyor, and the shredded material is separated from iron by the magnetic separator, and then it enters into the trommel screen to separate the aluminum chips, and the big piece of material enters into the eddy-current separator, which separates the aluminum and plastic by electromagnetic induction. This system adopts PLC control and dynamic real-time monitoring. It is characterized by low energy consumption per unit, large processing capacity, good economy, low maintenance cost and good processing effect. The whole set of production line adopts pulse dust removal, no dust pollution during operation.

Product Features

- Large pieces of scrap aluminum directly put, without the need for pre-disassembling links

- Wide choice of equipment models according to customer's output requirements

- Fully automated process from mixed material to single material, no need for secondary transportation

- Precise sorting of ferrous and non-ferrous metals

- Commit to 80-100 hours feeding test of the main machine to ensure stable performance

- CE certification, attention to process details, uniform standards, safety and aesthetics