Oily rags are a hazardous waste, proper disposal of oily rags is essential for industrial safety and compliance. Depending on the volume of oily rags generated, different shredding solutions may be appropriate. This article introduces two types of oily rag shredder machines available for sale: the dual-shaft linear shredder for small-scale disposal and the enclosed shredding system for large-scale disposal.

Dual-Shaft Linear Shredder: For Small-Scale Disposal

For facilities generating moderate amounts of oily rags, the dual-shaft linear shredder offers an efficient, compact solution.

Key Features:

- Compact Design: Fits in limited spaces.

- Robust Construction: Ensures durability.

- Efficient Shredding: Two powerful shafts cut through rags effectively.

Advantages:

- Cost-Effective: Affordable for small-scale operations.

- Ease of Use: Simple controls and low maintenance.

- Environmental Compliance: Proper disposal of oily rags.

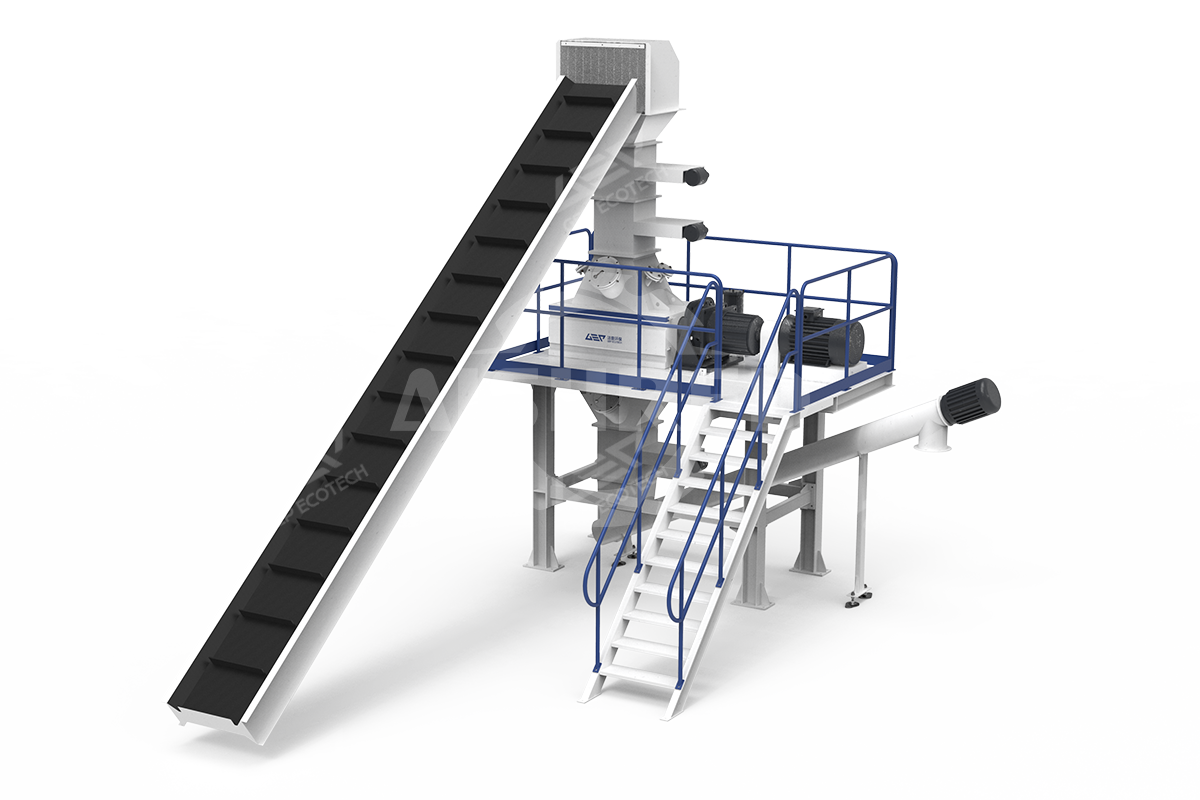

Enclosed Shredding System: For Large-Scale Disposal

For larger facilities producing significant volumes of oily rags, the enclosed shredding system offers a high-capacity, comprehensive solution.

Key Features:

- High Capacity: Processes large quantities continuously.

- Enclosed Design: Prevents environmental contamination.

- Automated Operation: Reduces manual handling.

Advantages:

- Efficiency: Handles large volumes quickly.

- Safety and Compliance: Enclosed and automated for safety.

- Resource Recovery: Recovers oil from shredded rags.

- Reduced Labor Costs: Automated processes lower costs.

Choose the dual-shaft linear shredder for small-scale disposal of oily rags, offering a compact and cost-effective solution. For large-scale operations, the enclosed shredding system provides high capacity, safety, and resource recovery benefits. Both machines ensure proper disposal, helping facilities comply with environmental regulations and maintain safety.