Pre-shredders are robust, heavy-duty machines commonly used in waste treatment facilities as the first step in material size reduction. Their primary function is to coarsely shred bulky or difficult-to-handle waste, significantly reducing its volume and making downstream processing more efficient. In many waste management lines, pre-shredding is a necessary step before feeding materials into finer shredders for further processing.

Powered by hydraulic systems, pre-shredders deliver high torque and strong cutting power, allowing them to handle a wide variety of materials—including municipal solid waste (MSW), industrial and commercial waste (C&I), bulky furniture, wood waste, and even light metals. Their versatility, durability, and ability to handle tough materials make them essential in integrated solid waste management systems, especially where large-scale and mixed waste streams are involved.

How to Choose a Pre-shredder?

Certain criteria must be considered before embarking on the acquisition of a pre-shredder. Choosing the right pre-shredder depends on your material type, capacity needs, and downstream process. Here are the key factors to consider:

Material Characteristics

Capacity & Throughput

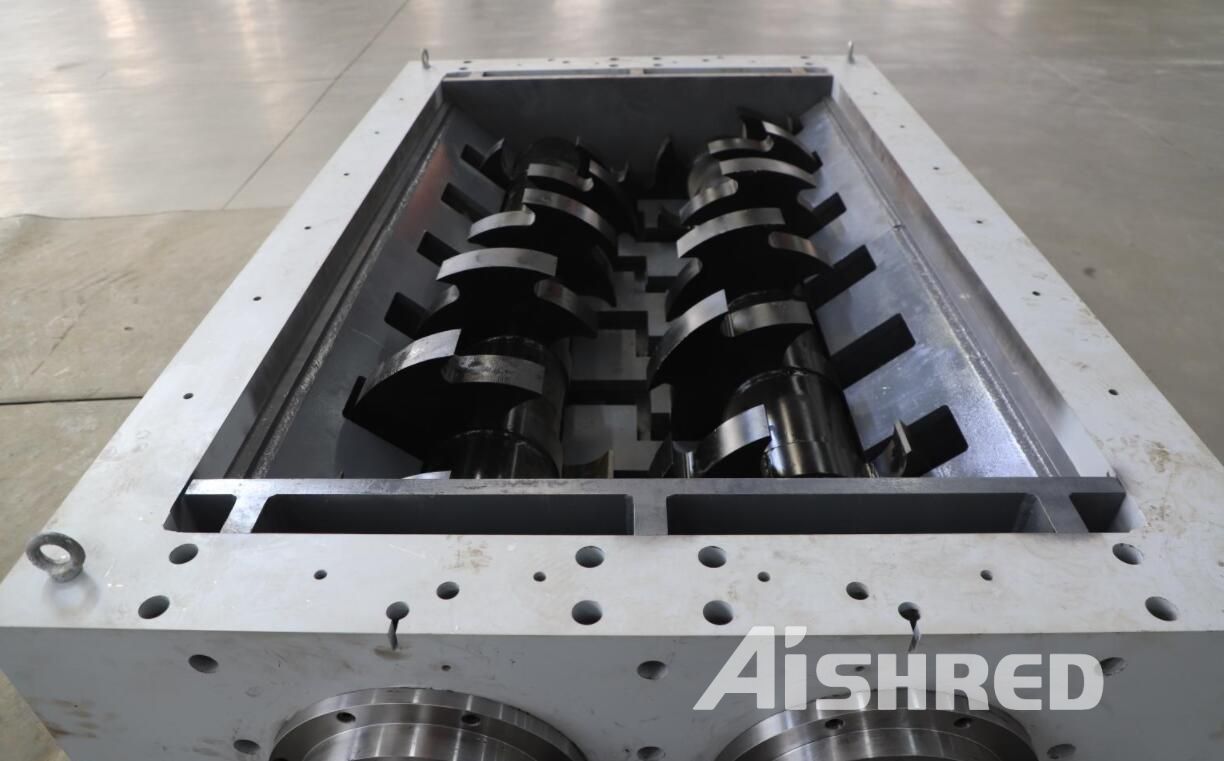

Cutting Technology

Maintenance & Durability

Integration Capability

Automation & Safety

GEP ECOTECH, as a leading solid waste disposal equipment manufacturer in China, can provide you with a suitable and customized pre-shredder solution tailored to your specific needs. Whether you are dealing with bulky municipal solid waste, construction and demolition debris, scrap metal, biomass, or industrial rejects, GEP ECOTECH's engineering team will analyze your material characteristics, processing goals, and site conditions to design the most efficient pre-shredding system. Partner with GEP ECOTECH to get a reliable, high-performance pre-shredder built to meet your current needs and future growth.