In the field of tire pyrolysis, batch pyrolysis equipment is popular because of its high efficiency and flexibility. For tires with a diameter of less than 1.2 meters, the whole tire can usually be directly put into the pyrolysis equipment for processing. However, in practice, many customers tend to shred the tires first and then send them to the batch pyrolysis equipment. Recently, our company received a customer from New Zealand, who clearly stated that he hoped to pre-shred the tires before pyrolysis in the hope of higher pyrolysis efficiency.

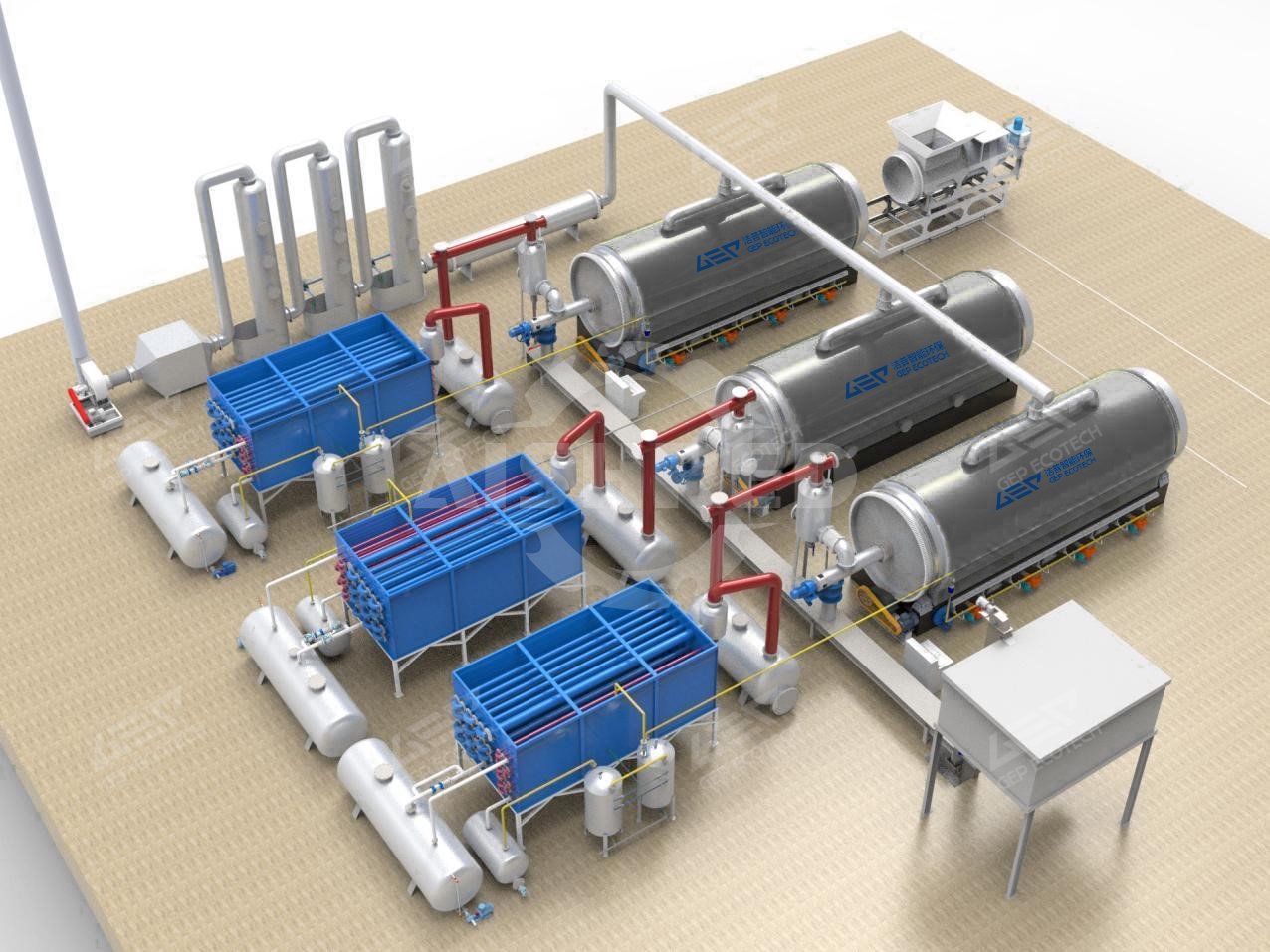

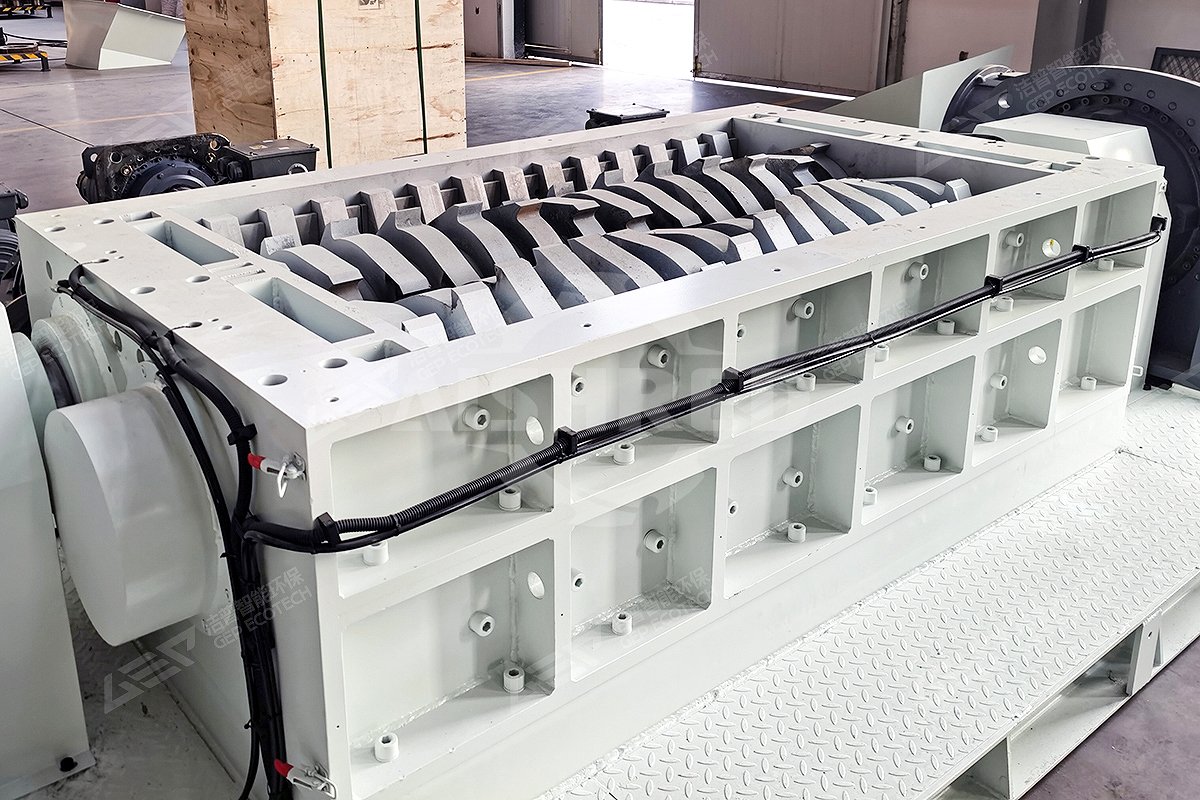

In response to the needs of this customer, our company recommended a production line configuration consisting of a hydraulic tire bead separator, a double-shaft shredder, and a feeding and dischage conveyor. This equipment can shred tires to a size of about 100 mm, which is very suitable as a feed for batch pyrolysis equipment.

![]()

So, why do some customers choose to pre-shred tires before sending them to pyrolysis equipment? The following is a detailed comparative analysis of the two processing methods: whole tire entry and pre-shred entry, to help you make a more informed choice.

Pyrolysis efficiency

- Whole tire entry: Due to the large volume of tires, it takes longer to heat and decompose evenly during the pyrolysis process, which may affect the overall pyrolysis efficiency.

- Pre-shredding before entering: The tire is shredded into smaller pieces, the surface area is significantly increased, and the contact with the pyrolysis medium is more sufficient, which helps to accelerate the pyrolysis speed and improve the pyrolysis efficiency.

Cost

- Whole tire entry: Although no additional investment in shredding equipment is required initially, in the long term, maintenance costs and replacement costs may increase due to greater equipment wear and tear.

- Pre-shredding before entering: It is necessary to invest in shredding equipment, but the pyrolysis efficiency of shredded tires is improved, which can shorten the pyrolysis cycle and reduce energy consumption, thus saving costs in long-term operation. In addition, equipment loss is reduced and maintenance costs are also reduced accordingly.

Product quality

- Whole tire entry: Due to uneven heating of different parts of the tire during the pyrolysis process, the quality of the pyrolysis product may be unstable, affecting the processing and application of subsequent products.

- Pre-shredding before entering: The shredded tire blocks are uniform in size and heated more evenly, which helps to obtain pyrolysis products with more stable quality and improve the processing performance and application value of subsequent products.

In summary, pre-shredding tires and then sending them to batch pyrolysis equipment for treatment has the advantages of improving pyrolysis efficiency, saving costs, and improving product quality. Of course, the specific treatment method should be determined according to actual conditions and needs. Our company can provide you with professional and customized solutions, and you are welcome to consult at any time.