As the global photovoltaic (PV) industry matures, a new wave of challenges is emerging: the large-scale retirement of aging solar panels. With a typical lifespan of 25–30 years, the first generation of solar modules is reaching its end-of-life, leading to a surge in decommissioned PV components.

End-of-Life Solar Panels

To address this growing concern, GEP ECOTECH has developed a comprehensive, efficient, and eco-friendly recycling solution for waste solar panels. Our system is engineered to extract maximum value from discarded PV modules, transforming waste into reusable materials while minimizing environmental impact.

What’s Inside a Solar Panel? Why Recycling Matters

A standard crystalline silicon solar panel contains:

- Glass (~76%)

- Polymers & Encapsulants (~9%)

- Aluminum Frames (~9%)

- Silicon (~4%)

- Copper, Silver, Lead, Tin, and other trace metals

While these materials are recyclable, traditional mechanical or thermal methods often fail to efficiently separate them or result in the loss of valuable elements like silver and copper. GEP ECOTECH’s solution goes beyond the limitations of conventional approaches.

GEP ECOTECH's Solar Panel Recycling System

Our recycling solution is a two-stage process integrating:

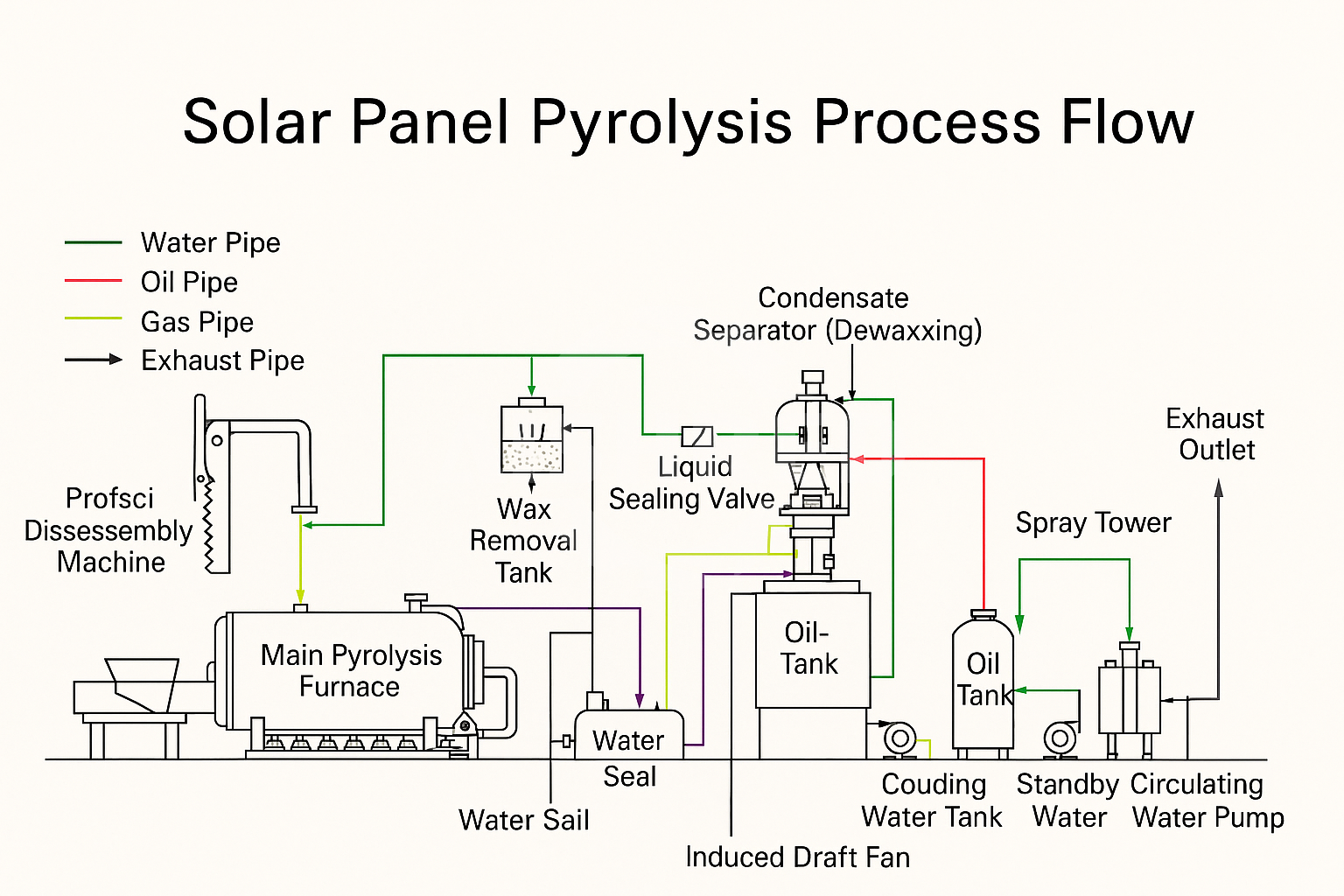

Thermal Decomposition (Pyrolysis)

- Purpose: To break down EVA encapsulants and organic polymers that bind components together.

- Technology: A horizontal rotary pyrolysis furnace, made of heat-resistant alloy steel, heats pre-treated PV modules to ~500–600°C.

- Process Outcome:

- Condensable oil vapors are recovered via high-efficiency condensation units.

- Non-condensable gas is filtered and reused as fuel for the pyrolysis chamber.

- Solid residues (glass, silicon, metals) are discharged for physical separation.

Multi-Stage Mechanical Separation

After pyrolysis, the remaining solid mixture enters a series of separation units:

- Crushers and Classifiers: Break down bulk material into manageable size.

- Density Separators: Separate silicon wafers from metals and glass.

- Color Sorting Machines: Distinguish copper wires from glass based on color recognition.

- Dust Collection Units: Recover fine silver particles generated during processing.

Key Advantages of GEP ECOTECH’s Solution

- Broad Compatibility: Capable of processing all types of solar panels — single-glass, dual-glass, and various mainstream configurations — regardless of age or manufacturer.

- Energy-Efficient & Self-Sustaining: The non-condensable gases produced during pyrolysis (C1–C4 hydrocarbons) are re-injected into the heating system, significantly reducing external fuel demand.

- Minimal Loss of Precious Metals: Our temperature-controlled pyrolysis minimizes oxidation and vaporization of silver and copper, ensuring higher recovery rates and material purity.

- High Throughput Capacity

- Daily processing capacity: 40–80 tons per system

- Suitable for industrial-scale recycling operations

- Requires only 8–10 operators per shift for a 40-ton line

- Environmentally Compliant

- No wastewater discharge — cooling systems use closed-loop recycled water.

- Exhaust gas purification — includes multi-stage sulfur and dust removal to meet national air emission standards.

- Dust-free slag removal — fully sealed discharging system ensures clean operation.

- Innovative Furnace Design

- Dual-direction rotating drum prevents material adhesion.

- Internal screw paddles ensure uniform heating and avoid clogging.

- Catalytic additives minimize wall fouling and enhance pyrolysis speed.

- Modular and Scalable: From small pilot lines to full-scale industrial installations, GEP ECOTECH’s equipment can be tailored to fit your processing volume and site layout.

GEP ECOTECH: A Partner You Can Trust

- Over 15 years of expertise in solid waste treatment equipment

- Global project presence in Asia, Europe, the Middle East, and Africa

- ISO, CE certified systems with customizable layouts

- Full lifecycle support: design, installation, commissioning, training, and maintenance