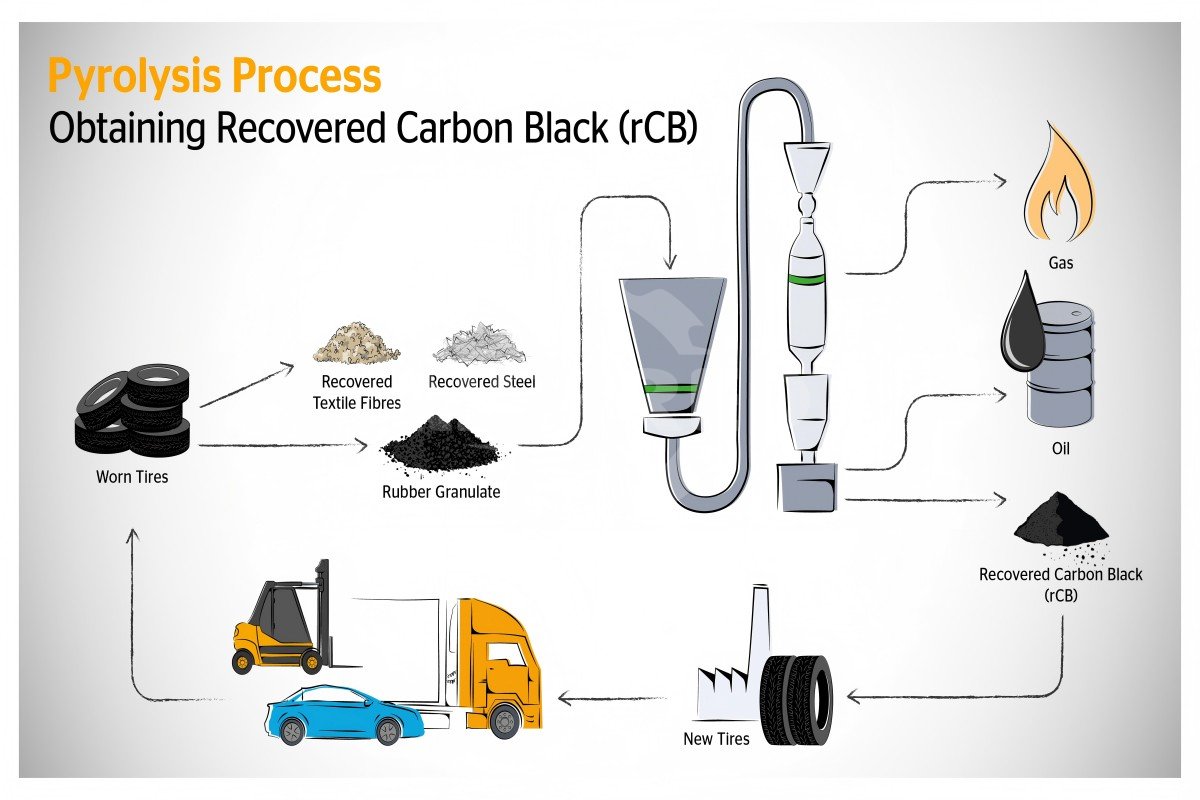

Tire pyrolysis and oil refining is a process of converting waste tires into useful resources such as fuel oil, carbon black, and combustible gas through high-temperature pyrolysis technology. This technology can not only effectively process waste tires, reduce environmental pollution, but also achieve resource recycling. The following are the main processes and key points of tire pyrolysis and oil refining:

1. Basic principle

Heat waste tires to a certain temperature (usually 300 ℃ -500 ℃) in an anaerobic or low oxygen environment, causing their polymer to undergo pyrolyzing and produce the following products:

- Pyrolysis oil: can be used as fuel oil or further refined.

- Carbon black: can be used in industrial fields such as rubber products and coatings.

- Combustible gas: mainly composed of methane, hydrogen, etc., can be used as fuel for pyrolysis process.

- Steel wire: The steel wire in tires can be recycled and reused.

2. Main process

1) Tire pretreatment: Remove impurities (such as mud, stones) from the tires.

Use a tire shredder to shred the tires into small pieces (usually 2-5 cm) for pyrolysis.

2) Feeding material: The shredded tires are fed into the pyrolysis reactor through the feeding system.

3) Pyrolysis reaction: In the pyrolysis reactor, the tires are heated in an anaerobic environment to undergo a pyrolysis reaction, producing an oil gas mixture and solid residue (carbon black and steel wire).

4) Oil and gas separation and condensation: The oil and gas mixture produced by pyrolysis enters the condensation system and is separated into liquid oil and combustible gas after cooling. Liquid oil is stored after filtration and purification. After purification, combustible gas can be used for heating systems or power generation.

5) Carbon black and steel wire treatment: Carbon black is discharged from the reactor and used as an industrial raw material after cooling, grinding, and packaging.

Steel wire is separated and recovered by magnetic separator.

6) Waste gas treatment: The uncondensed exhaust gas is purified to ensure compliance with environmental emission standards.

As a professional tire disposal equipment provider, GEP ECOTECH can provide you with customized tire disposal solutions. If you have any requirements, please feel free to contact us.