GEP ECOTECH's rubber granules production line is a high-performance solution designed to recycle waste tires into valuable rubber granules. It is suitable for various tire types—including passenger car, truck, and light commercial tires. Tailored solutions for OTR (Off-the-Road) tires are also available upon request.

The main final products—rubber granules (around 1-10mm) serve a wide range of applications: playground surfaces, running tracks, rubber flooring, and asphalt modification. And the size can be adjusted. We can also get rubber powder (<1mm) from the line, which is ideal for reclaimed rubber, waterproofing materials, insulation, and molded rubber products.

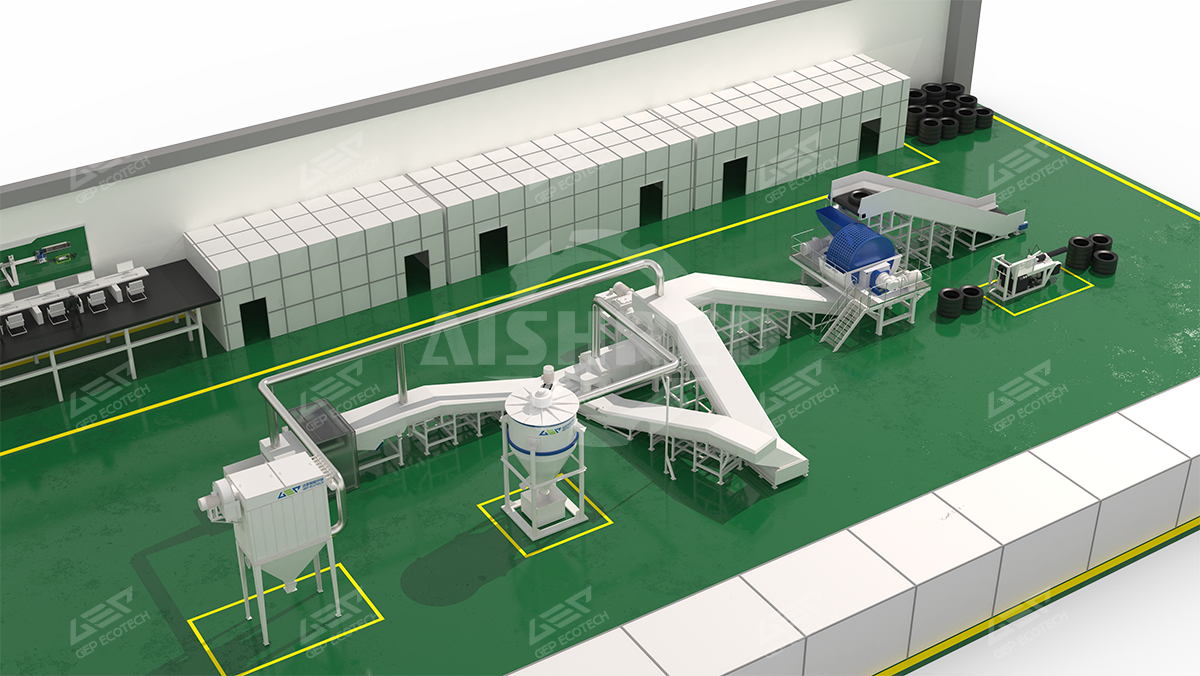

Main Working Process of the Production Line

Step 1: Tire Debeading

For tires ranging from 800mm to 1200mm in diameter, a tire debeader is used to remove the bead wires. This step helps protect downstream equipment and facilitates steel separation.

Note: Smaller tires may skip this step and go directly to shredding.

Step 2: Primary Tire Shredding

De-beaded (or small whole) tires are fed into a heavy-duty tire shredder with high shearing force. The shredder is equipped with an integrated trommel screen or split type roller screen to control discharge size, typically producing rubber chips of 2-3 inches.

Alternatively, an integrated slicing and dicing machine can be used to process whole tires directly into uniform rubber chips, offering a compact and efficient reduction method (without the tire debeading process).

Step 3: Rubber Breaking Unit—Secondary Size Reduction

The rubber chips are transferred to the rubber breaking unit, which includes:

- Rubber breaker: Further granulating rubber chips into rubber granules.

- Magnetic separator: Extracting residual steel wires from the rubber.

- Vibrating screen: Sorting and classifying the particles by size to meet required specifications.

Step 4: Fiber Separator—Fiber Removal

It is used to remove fibers from the rubber granules.

Through the above steps, the result is clean, high-quality rubber granules or powder ready for downstream applications. To support smooth operation, the system is equipped with integrated intelligent control cabinet, ensuring high stability and automation throughout the process.

Key Advantages of the Solution

- High automation for continuous operation with low labor input (5-6 workers for the whole line)

- Clean steel wire separation for higher product purity (≥98%)

- Customizable output size to meet diverse market demands (as fine as 120mesh)

- Heavy-duty design for long service life (15-20 years for the core equipment) and minimal maintenance

Scalable and Customizable

The rubber granules production line by GEP ECOTECH is modular and scalable. Whether you are a startup or upgrading an existing facility, the system can be configured to match your capacity and product specifications. GEP ECOTECH also offers full system integration, from raw material feeding to packaging, ensuring a customer-oriented solution, compliant with the local requirements.

Ready to turn waste tires into valuable products? Contact GEP ECOTECH today to learn more about how our rubber granule solutions can power your recycling business.