The choice between a single-shaft shredder and a double-shaft shredder for circuit board crushing depends on various factors, including the specific requirements of your application, the characteristics of the circuit boards, and the desired output.

Single-Shaft Shredder

Advantages:

- Simplicity: Single-shaft shredders are simpler in design, consisting of a single rotor with blades or hammers. This simplicity can make them easier to operate and maintain.

- Lower Initial Cost: Generally, single-shaft shredders may have a lower upfront cost compared to double-shaft shredders.

- Energy Efficiency: Single-shaft shredders may be more energy-efficient for certain applications.

Considerations:

- Output Size: Single-shaft shredders can produce a more uniform, fine output size, which can be advantageous for certain recycling processes.

- Material Feed: If your circuit boards are relatively uniform in size and do not contain significant variations in hardness or material composition, a single-shaft shredder might be suitable.

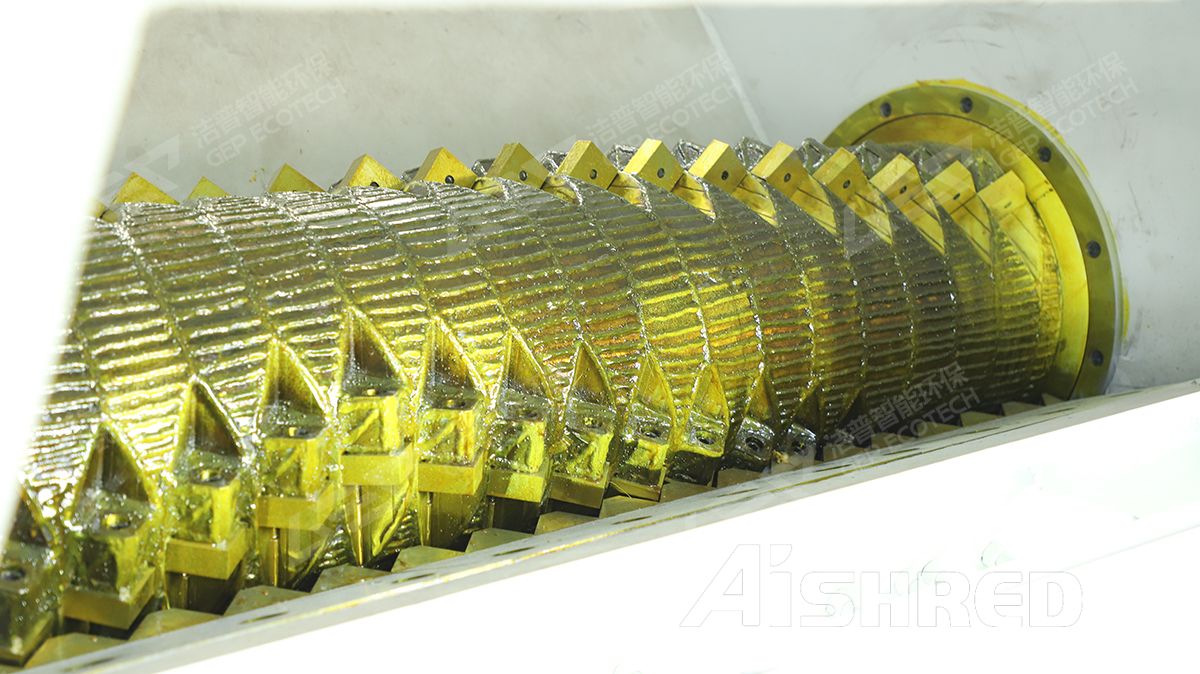

Double-Shaft Shredder

Advantages:

- Versatility: Double-shaft shredders are often more versatile and can handle a wider range of materials and variations in feedstock.

- Greater Torque: Double-shaft shredders typically generate more torque, making them better suited for challenging materials and applications.

- Effective for Inhomogeneous Materials: If your circuit boards vary in size, composition, or have components with different hardness, a double-shaft shredder might be more effective.

Considerations:

- Complexity: Double-shaft shredders have a more complex design with two interlocking rotors. While this provides versatility and high production capacity, it can also result in increased maintenance complexity.

- Higher Initial Cost: Double-shaft shredders tend to have a higher initial cost compared to single-shaft shredders.

Video of Dual Shaft Shredder Crushing Circuit Boards

In summary, both single-shaft and double-shaft shredders can be suitable for circuit board crushing, but the choice depends on the specific characteristics of your circuit boards and your processing requirements. If your circuit boards are relatively uniform, a single-shaft shredder might be sufficient. If you deal with varied materials or need higher torque, a double-shaft shredder could be more suitable. Consulting with shredder manufacturers or experts in the field can provide tailored advice based on your specific needs.