Wind power, as a kind of green energy, is developing rapidly worldwide in the 21st century. At the same time, the material of wind turbine blades has become more and more diversified, mainly including long fiber composites, glass fiber composites and carbon fiber composites. In the field of new energy development, composite materials are mainly used to manufacture wind turbine blades. However, with the passage of time, these wind blades have gradually entered the phase of elimination and replacement.

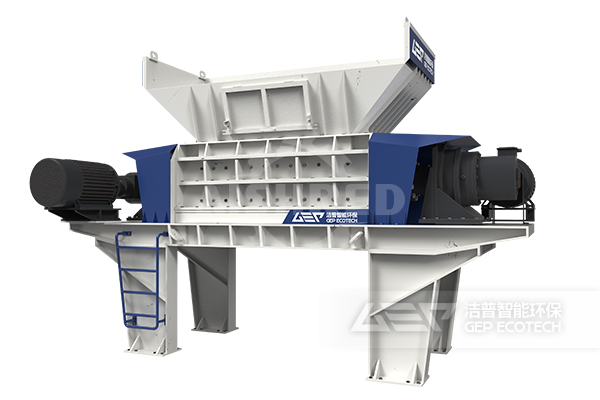

Due to the large size and heavy weight of wind turbine blades, their disposal is indeed a difficult project. Even if they are partially cut in the early stage, they still need to be shredded before they can be disposed of in the next step. In the choice of shredding equipment, the twin-shaft shredder can meet the shredding needs of wind turbine blades with high quality. First of all, the wind turbine blades need to be cut to a suitable size, and then the material is fed into the shredding chamber through the conveying equipment to complete the initial shredding, and the discharge size is usually under 200 mm, which initially realizes the reduction of the material capacity and volume. In addition, some customers may have smaller requirements for the discharge size, we can also add secondary shredding, so that the final discharge size is controlled between 50 mm and 80 mm, in order to meet their subsequent application requirements.

In industrial shredding production, the disposal of wind turbine blades has specific requirements. Whether you want to achieve capacity reduction or have other needs and applications after shredding, AIShred can provide customized services depending on the project. You are always welcome to call us to inquire about your project.