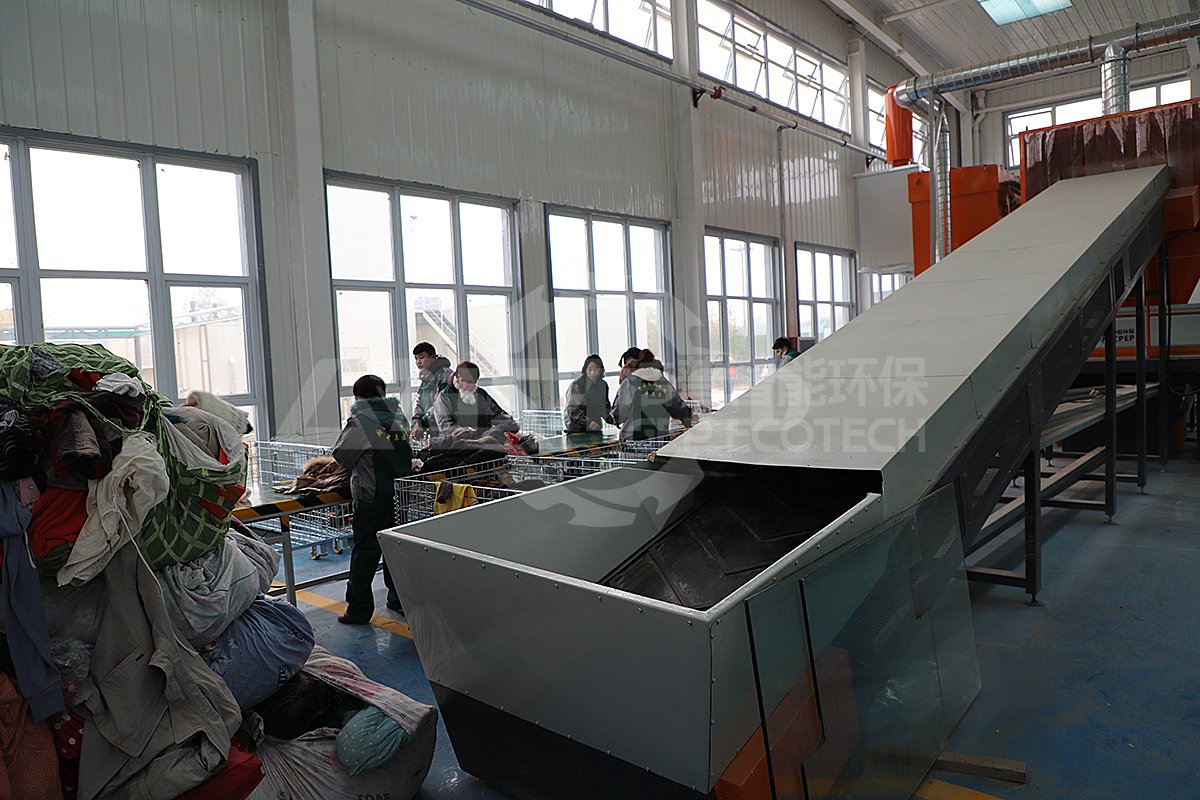

Clothes, broken sheets, waste cloth, these originally to be landfilled or incineration for the fate of the textile trimmings, with the fabric shredder, but has a different “destiny”.

Fabric shredders are a common type of industrial equipment used to shred various types of fabrics and textiles into small pieces for subsequent processing. They are commonly used in textile mills, garment factories, recycling plants and other places where large quantities of fabrics need to be processed.

The GEP ECOTECH SHREDDER is a machine designed to handle a wide range of hard leather and leather bags, soft, fibrous wastes, and has demonstrated excellent performance in handling textile wastes in particular. It drives the rotor of the movable knife to rotate at a low speed by driving the knife shaft by the power system, and the textiles such as waste clothes, fabrics, carpets and other textiles are quickly shredded into small pieces through mutual tearing and shearing between the knives, and even the degree of fine shredding can be achieved at the fiber level. This process not only reduces the volume of textile waste and facilitates subsequent storage and transportation, but more importantly, it provides the possibility of secondary utilization of textiles.

Shredded textile fragments can be further transformed into new raw materials through processes such as sorting, cleaning, melting or recycling fibers. For example, some high-quality fibers can be melted down and recycled into new textiles, while low-quality fibers can be transformed into filler materials, soundproofing materials or components of composite materials. In addition, shredded textiles can also be used as raw materials in the paper and insulation industries, which broadens the recycling channels of resources.