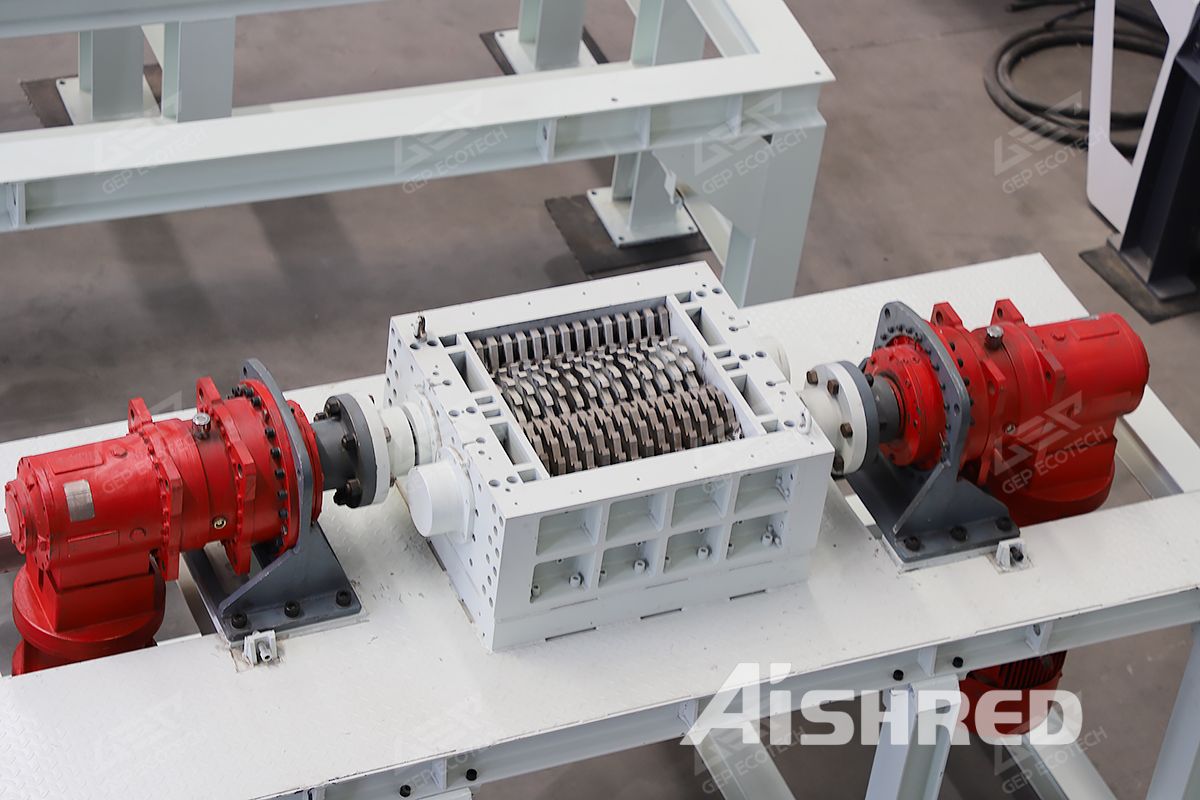

A two-shaft aluminum beverage can shredder is an industrial machine designed specifically for shredding and reducing the size of aluminum beverage cans. These shredders play a crucial role in recycling operations, as they help process aluminum cans into smaller particles for further recycling and material recovery.

Video of Twin-Shaft Shredder Shredding Aluminum Cans

Key Features of a Two-Shaft Aluminium Beverage Can Shredder

- Dual Shafts: As the name suggests, a two-shaft shredder has two parallel shafts equipped with sharp blades or cutting discs. This design enhances the efficiency of shredding and ensures a more thorough reduction of material.

- Cutting Blades: The cutting blades on each shaft are strategically positioned to cut through aluminum cans effectively. The blades are designed to withstand the abrasive nature of metal shredding.

- High Torque and Power: Two-shaft shredders typically have high torque and power to handle the tough and rigid nature of aluminum cans. This is important for achieving efficient and effective shredding.

- Durable Construction: The machine is built with durable materials to withstand the wear and tear associated with shredding metal. The construction should be robust to handle the abrasive properties of aluminum.

- Safety Features: Safety features such as emergency stop buttons, safety sensors, and protective guards are incorporated to ensure safe operation, especially in industrial settings.

- Variable Speeds: Some models may offer variable speed controls, allowing operators to adjust the shredding speed based on the type and density of the material being processed.

- Size Reduction: The primary function of a two-shaft aluminum can shredder is to reduce the size of aluminum cans into smaller particles, facilitating further processing and recycling.

Considerations for Choosing Two-Shaft Aluminium Can Shredders

- Capacity: Assess the volume of aluminum cans you need to process. Choose a shredder with the capacity that meets your production requirements.

- Material Handling: Ensure that the shredder is designed to handle aluminum cans efficiently. Some models may have features specific to metal shredding.

- Safety Measures: Given the nature of metal shredding, safety features are critical. Ensure the machine meets safety standards and regulations.

- Maintenance Requirements: Evaluate the ease of maintenance. Shredders with features like easy blade replacement and cleaning can reduce downtime.

- Integration with Downstream Processes: Consider how well the shredder can integrate with downstream processes, such as metal sorting systems or material recovery facilities.

- Environmental Impact: Choose shredders designed with energy efficiency features to minimize environmental impact.

- Compliance with Regulations: Ensure that the shredder complies with environmental and safety regulations applicable to metal shredding.

- Brand Reputation: Choose a shredder from a reputable manufacturer with a history of producing reliable and efficient industrial equipment.

Before making a purchase, thoroughly research and compare different models, considering your specific needs, budget, and the reputation of the manufacturer. Additionally, inquire about warranties, technical support, and after-sales service to ensure a smooth and reliable operation of the two-shaft aluminum can shredder.