The management of end-of-life tires has always been an important issue in environmental conservation. Billions of scrap tires are generated globally every year. These accumulated waste not only take up a lot of space but can also cause fires and release harmful chemicals, posing potential threats to the environment and health. Effective recycling of scrap tires is receiving increasing attention. Fortunately, innovative developments are taking place in this area. There are now more mature and environmentally friendly treatment methods for end-of-life tires, which can be converted into derived fuels, recycled rubber, fuel oil, or other useful substances.

GEP ECOTECH boasts extensive expertise in tire recycling, offering the capability to design and implement complete production lines tailored to the specific needs. Our versatile range of equipment combinations enables us to meet diverse tire and other rubber products recycling needs—be it recycling rubber chips, granules, powder, or for pyrolysis—at different stages and scales.

Tire Derived Fuel(TDF)

Tire-derived fuel, sourced from shredded rubber blocks, offers a higher calorific value than coal and serves as a substitute for traditional fossil fuels in power generation or heating. Metal content allows it to improve cement quality, making it highly favored in cement clinker production.

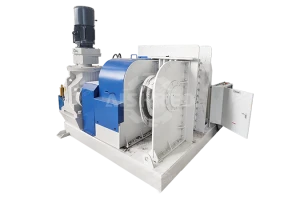

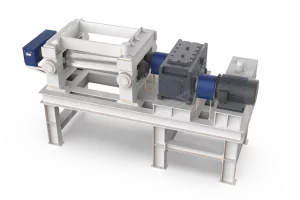

The production of tire-derived fuel is relatively simple, a GDT tire shredder can complete this task. For off the road tyres, steel wire separators can be used to separate the steel wires, which can create additional profits for recycling.

Recycled Rubber

Materials recycled from discarded tires or other rubber materials can be used to create various recycled rubber products: rubber mulch for playgrounds, landscaping, etc.; rubber granules for track surfaces or as asphalt additives to enhance road performance; finer rubber powder for manufacturing new rubber products or as supplementary ingredients.

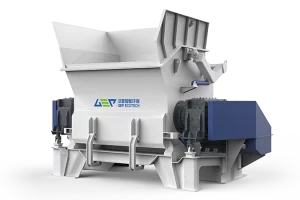

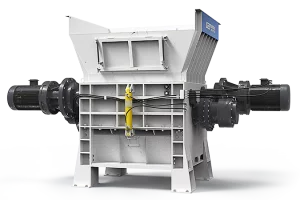

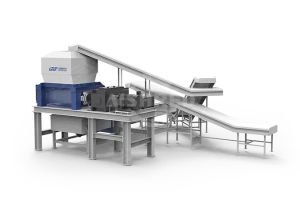

The primary production processes for recycled rubber involve shredding, granulating, and grinding, with auxiliary steps for steel wire and fiber separation.

Pyrolysis

Pyrolysis is a high-temperature treatment process that involves heating discarded tires or rubber materials at high temperatures in a low-oxygen environment to trigger a chemical reaction. Under these conditions, rubber materials decompose into oil, gas, and carbon black. Temperature and reaction time during pyrolysis significantly impact the properties of the final products.

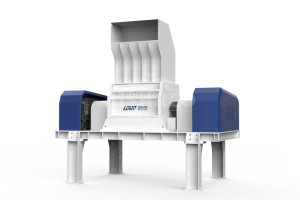

Pre-processing of waste tires into smaller sizes before entering the pyrolysis chamber helps enhance reaction rates and reduce energy consumption.

Microwave Pyrolysis

Microwave pyrolysis is an emerging technology that utilizes electromagnetic waves to uniformly heat materials, resulting in higher thermal efficiency and process controllability. This innovative method reduces reaction times, optimizes the pyrolysis process, and enhances the quality of the final products. This environmentally friendly and efficient approach offers a promising solution for sustainable treatment of rubber materials, providing an alternative pathway for the eco-friendly recycling of scrap tires.