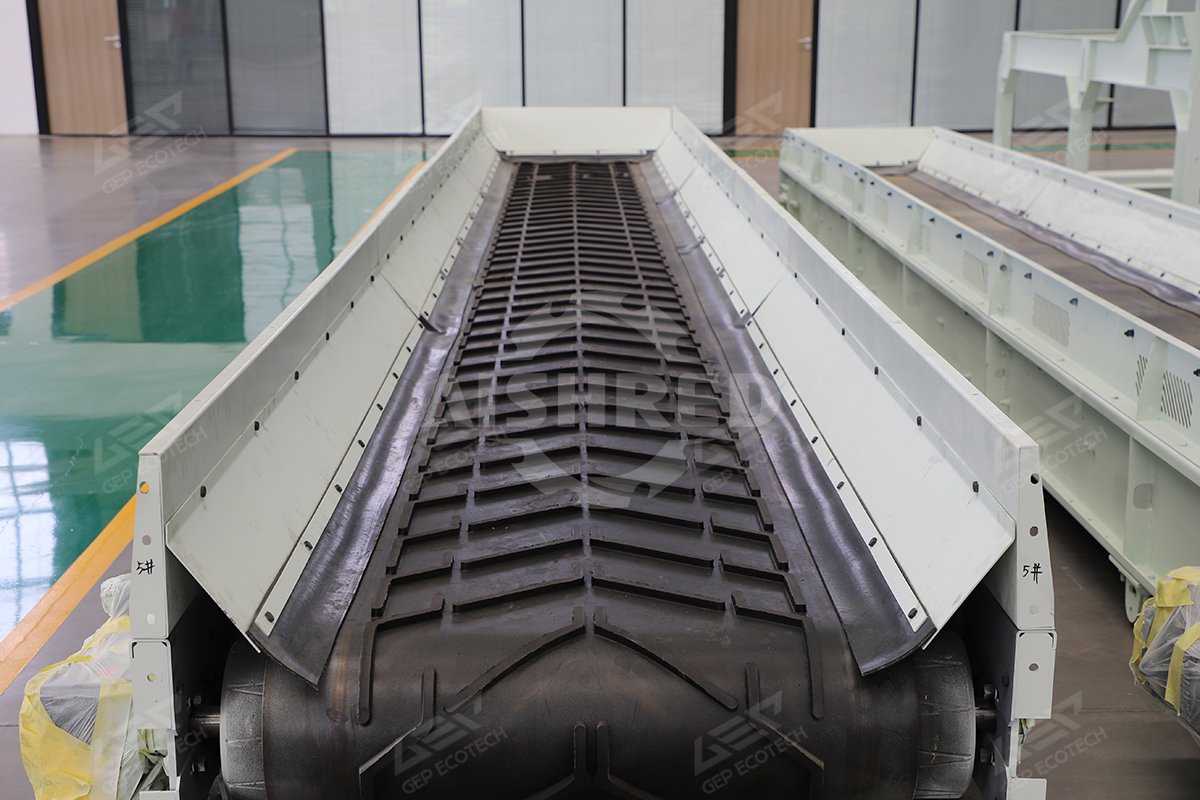

Choosing between a belt conveyor or a screw conveyor is indeed a crucial choice in biomass fuel processing systems. Based on different technical routes and different understandings of project requirements, belt conveyors are generally the more cost-effective, reliable, and energy-efficient choice for horizontal or small angle inclined transportation of crushed biomass fuel. Screw conveyors are usually suitable for specific working conditions, such as short distances, vertical lifting, or extremely limited space.

Detailed Comparisons Between Belt Conveyor and Screw Conveyor

We can compare these two conveyors from several key dimensions:

| Item | Belt Conveyor | Screw Conveyor | Remarks |

| Working principle | Belt conveyors transport materials through static friction between the belt and the material. | The screw conveyor drives materials forward through rotating spiral blades. | / |

| Applicable materials | Widely applicable, especially suitable for loose, non viscous, granular or block materials. | Limited, suitable for powdery, granular, and semi fluid materials. | Shredded biomass is usually loose, making it more compatible with belt conveyors. |

| Conveying distance | The long-distance advantage is obvious (up to tens or even hundreds of meters). | Short distance (usually<20 meters), if too long, power consumption will increase dramatically, and the suspended bearings in the middle are prone to damage. | If your project has a certain distance from the shredder to the silo or combustion equipment, a belt conveyor is a more reasonable choice. |

| Conveying capacity | Very large, the belt can be made very wide, and the speed can also be adjusted. | Relatively small, the conveying capacity is limited by the diameter and speed of the screw. | For alternative fuel projects, the processing capacity is usually large, and belt conveyors can better meet the demand for future capacity increase. |

| Energy consumption | Lower. The main energy consumption comes from driving the drum and overcoming belt friction, with high efficiency. | Higher. The friction between materials and blades, pipe walls, and suspended bearings is severe, resulting in high power consumption. | Operating costs are key. The belt conveyor can save you a lot of electricity costs, and in the long run, the benefits are significant. |

| Maintenance and Lifespan | Easy maintenance and long lifespan. The main vulnerable parts are rollers and belts, which are easy to replace. | Frequent maintenance and relatively short lifespan. Screw blades and pipe walls are prone to severe wear and tear, making maintenance difficult. | Biomass materials are usually abrasive and can accelerate the wear of screw blades. Belt conveyors are more durable, ensuring production continuity and reducing downtime losses. |

| Sealing and Environmental Protection | It can be fully sealed (such as with a dust cover) to prevent dust from escaping and meet environmental requirements. | Sealed structure, theoretically no dust leakage. | Both can be well sealed. |

| Installation and flexibility | Installation requires a certain amount of space, but the layout is flexible and can be designed with multiple twists and turns. | Compact structure, small space occupation, suitable for linear conveying with narrow space. | It needs to be judged based on the actual layout of your factory. |

Under What Circumstances Should Belt Conveyors Be Prioritized?

- Reliability first: The core of biomass fuel production lines is stable and continuous operation. The belt conveyor has a simple structure and low failure rate, which can minimize the production stoppage of the entire line caused by the failure of the conveying equipment.

- Economic considerations: In terms of cost, when purchasing equipment, not only should you consider the price, but GEP ECOTECH will also calculate the full lifecycle cost for you. The lower energy consumption and maintenance costs of the belt conveyor can offset the possible initial investment price difference within 1-2 years, and save you money every year thereafter.

- Adapt to material characteristics: The shredded biomass fuel has different sizes, edges, and abrasiveness. The gentle conveying method of belt conveyor (friction driven) can reduce the secondary shredding of materials and equipment wear. The "strong pushing" method and internal bearings of the screw machine are easily entangled or stuck by long strip materials.

- Reserved for the future: Belt conveyors are easier to expand (such as increasing belt speed or widening belts), leaving space for you to increase production capacity in the future.

Under What Circumstances Will Screw Conveyors Be Used?

Of course, screw conveyors also have their irreplaceable advantages, which may be suitable in the following scenarios

- Short distance vertical lifting: For example, materials need to be lifted diagonally from an underground pit onto a device.

- Extremely limited space: Transportation needs to be completed in a very narrow and enclosed space.

- Measurement and feeding: Small high-speed spirals are often used as precise measuring and locking equipment.

- Transporting viscous or semi fluid materials such as sludge.

Since our establishment, GEP ECOTECH has provided stable and reliable biomass alternative fuel solutions and corresponding waste recycling plants customers from multiple countries. We carefully consider the long-term stable operation and comprehensive benefits of your entire production line. If there is a specific location on site that does require a screw conveyor for lifting or feeding, we will also partially adopt it in the plan. What we hope to provide you is not a pieced together low-priced solution, but a stable, efficient, and holistic solution that can create maximum value for you.