Industrial waste management plays a crucial role in maintaining a clean and sustainable environment. With the advancing technology, the implementation of double-shaft shredders and single-shaft shredders has proven to be a highly effective solution in efficiently processing and disposing of industrial waste. This article aims to explore the benefits and optimization opportunities presented by these shredding machines in industrial waste management.

Double-Shaft Shredders

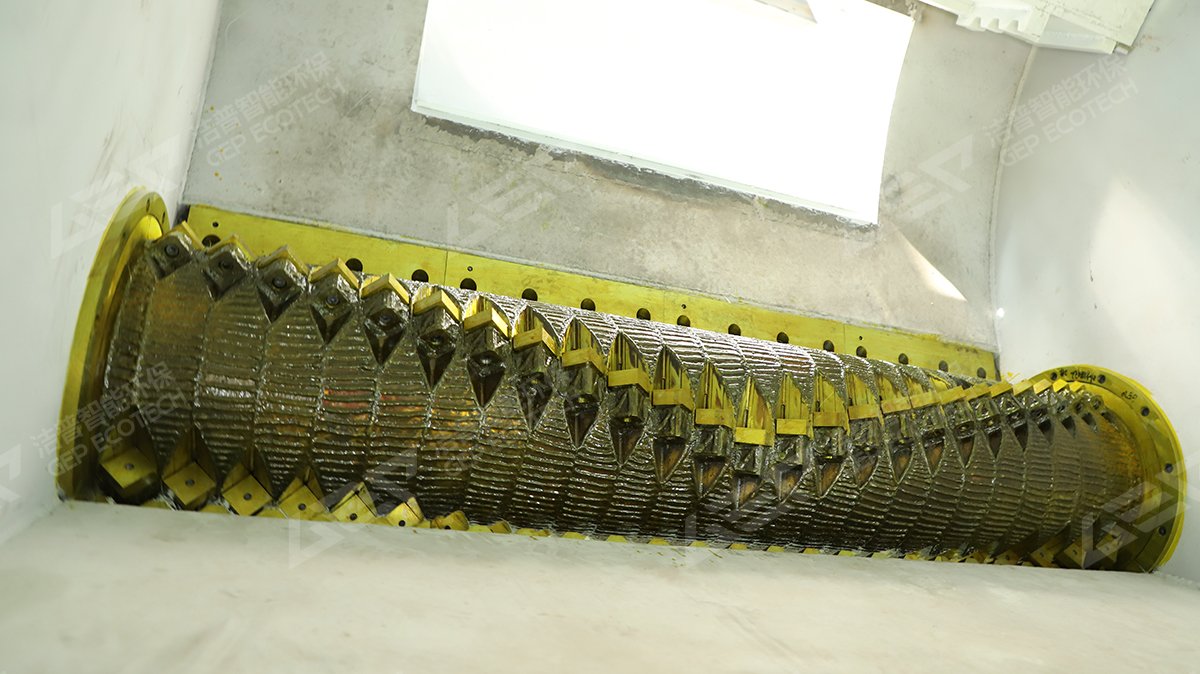

Double-shaft shredders are robust machines that operate with two interlocking cutting shafts. These shredders excel in handling a wide variety of industrial waste materials such as plastics, rubber, wood, and metals. The unique design and cutting mechanism of double-shaft shredders enable them to achieve high throughput and consistent particle size reduction, making them ideal for large-scale industrial waste processing facilities.

Advantages

- Versatility: Double-shaft shredders can efficiently process various types of industrial waste, reducing the need for separate shredding processes.

- High throughput: The dual-shaft design enables these machines to handle large volumes of waste material, ensuring speedy processing and increased productivity.

- Consistent output: Double-shaft shredders produce uniformly shredded particles, facilitating downstream sorting and recycling processes.

- Durability: These shredders are built to withstand heavy-duty usage in demanding industrial environments, ensuring long-term reliability and cost-effectiveness.

Optimization Opportunities

- Advanced automation: Integrating double-shaft shredders with automated feeding and discharge systems can enhance operational efficiency and reduce human intervention.

- Intelligent control systems: Implementing smart control systems will enable real-time monitoring and adjustments, optimizing shredding parameters for improved performance.

- Material-specific customization: Tailoring double-shaft shredders to handle specific waste materials can optimize efficiency and output quality.

Single-Shaft Shredders

Single-shaft shredders are renowned for their simplicity and effectiveness in shredding a wide range of industrial waste, such as cardboard, paper, textiles, and electronic waste. These machines operate with a single rotating shaft fitted with blades or hammers that cut and shred the materials into smaller pieces.

Advantages

- Cost-effective: Single-shaft shredders are relatively affordable and require minimal maintenance, making them an economical choice for small to medium-sized waste management facilities.

- Easy operation: These shredders have user-friendly interfaces, allowing operators to control and monitor the shredding process efficiently.

- Space-saving: Single-shaft shredders have a compact design, making them suitable for facilities with limited space constraints.

- Energy-efficient: With advanced motor and cutting technology, single-shaft shredders consume less energy while delivering optimal performance.

Optimization Opportunities

- Knife customization: Tailoring the shredder's blade configuration to match the specific waste materials can enhance shredding efficiency and prolong blade life.

- Integration with sorting systems: Combining single-shaft shredders with automated sorting systems enables efficient segregation of shredded waste, facilitating recycling and recovery processes.

- Safety enhancements: Implementing safety features such as sensors and interlocks can prevent accidents and ensure the well-being of operators.

The utilization of double-shaft shredders and single-shaft shredders in industrial waste management brings numerous advantages and optimization opportunities. These machines offer efficient waste processing, consistent output quality, and increased productivity. By exploring customization options and integrating automation, waste management facilities can further enhance their efficiency and contribute to a more sustainable future.