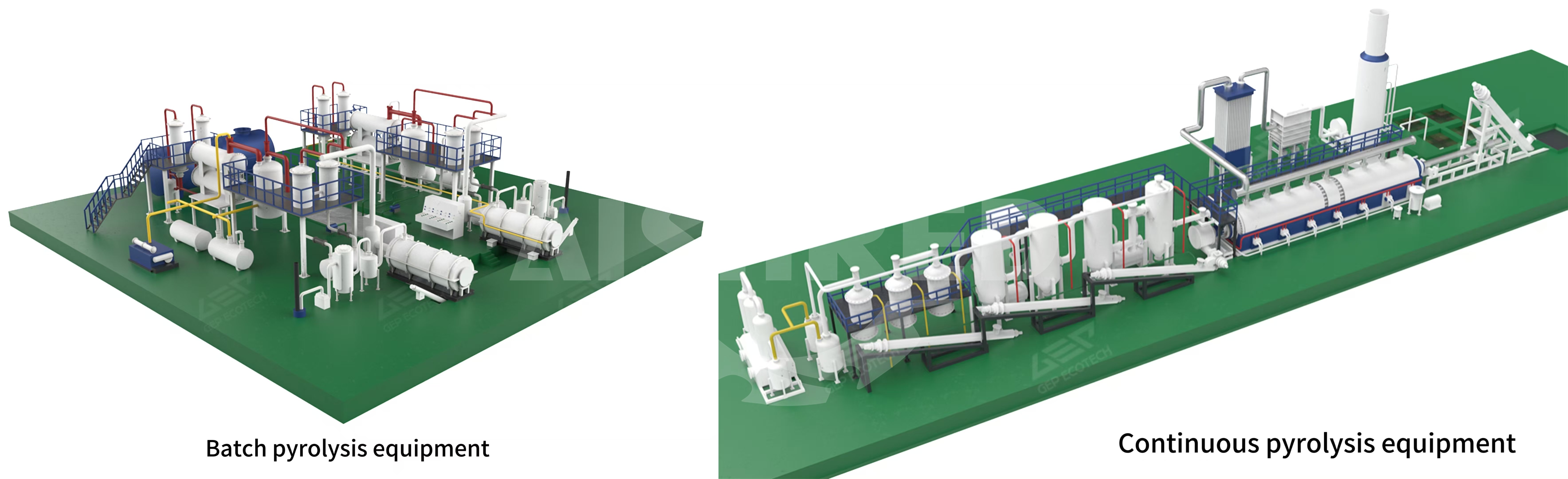

Currently, waste tire pyrolysis and oil refining equipment mainly comes in two types: batch and continuous. When selecting pyrolysis and oil refining equipment, companies often face the dilemma of choosing between batch and continuous equipment. Below, we will compare these two types of equipment in detail from key perspectives such as production efficiency, material requirements, environmental performance, automation level, and cost and return on investment, to help you make a more informed decision.

1. Production Efficiency

Batch equipment operates in a batch processing mode, handling a batch of waste tires at a time. After each batch is completed, the equipment needs to be shut down for cooling, discharging products and residues, and then starting the next batch. Although this mode is simple to operate, the frequent start-stop cycles result in shorter effective operating times and lower production efficiency.

Continuous equipment, on the other hand, enables 24-hour uninterrupted production. Raw materials are continuously fed into the reaction system via a conveying device, and products are continuously discharged without significant downtime, leading to higher production efficiency.

2. Material Requirements

Batch equipment has relatively lower requirements for material pretreatment and can typically accept whole tires or simply shredded waste tires. The design of this equipment allows larger material sizes to enter the reactor, reducing the complexity of pretreatment. However, larger material sizes may lead to lower pyrolysis efficiency, affecting the quality and yield of the products.

Continuous equipment has stricter material requirements. To ensure uniform and continuous reactions, raw materials usually need to undergo fine pretreatment, achieving particle or powder sizes below 5mm. Although this increases the complexity of pretreatment, it significantly improves pyrolysis efficiency and product quality.

3. Environmental Performance

Batch equipment uses closed anaerobic pyrolysis technology and is equipped with a flue gas purification system, effectively reducing exhaust emissions. However, due to its intermittent operation mode, the equipment may produce instantaneous high-concentration exhaust emissions during start-stop cycles, which can impact environmental performance.

Continuous equipment adopts a fully enclosed system with advanced exhaust gas treatment devices, effectively reducing pollutant emissions. Its continuous operation mode avoids the environmental issues that may arise from the start-stop cycles of batch equipment, complying with stricter environmental standards. Additionally, the efficient pyrolysis process of continuous equipment can more thoroughly convert organic components in waste tires, reducing residues and waste generation.

4. Automation Level

Batch equipment is relatively simple to operate but has a lower level of automation. The equipment usually requires manual or semi-automated feeding and slag discharge operations, resulting in higher labor intensity. This type of equipment is suitable for companies with limited automation requirements and budget constraints.

Continuous equipment is typically equipped with a PLC intelligent control system, enabling highly automated operations. The automated control system not only improves production efficiency but also reduces manual intervention and labor intensity. Moreover, the higher level of automation contributes to stable equipment operation and consistent product quality.

5. Cost and Return on Investment

Batch equipment has a lower initial investment, with a simple structure suitable for small to medium-scale production. Due to its lower production efficiency, the unit production cost is relatively higher. However, for companies with limited funds or smaller production scales, batch equipment is a more economical choice.

Continuous equipment requires a higher initial investment, with a complex structure suitable for large-scale production. Although the initial investment is larger, its efficient production mode can significantly reduce unit production costs and improve economic benefits. In the long run, continuous equipment offers a higher return on investment and is suitable for companies with larger production demands.

Both batch and continuous tire pyrolysis oil refining equipment have their own advantages and disadvantages, catering to different production scenarios and needs. When selecting equipment, companies should comprehensively consider factors such as production scale, budget, environmental requirements, and the need for production efficiency and product quality. For small to medium-scale production or pilot projects, batch equipment is a more economical choice, while for large-scale industrial production, continuous equipment offers greater advantages.

If you have related needs and are unsure how to choose, feel free to contact us, and we will provide you with a suitable selection plan!