Modern society has a huge demand for paper. In recent years, as environmental protection efforts have increased, traditional pulp and paper making has been greatly reduced and replaced by more environmentally friendly recycled paper making.

However, due to the different ways and quality of waste paper recycling, recycled waste paper may be mixed with other impurities, resulting in a large amount of solid waste in the manufacturing process of recycled paper, also known as "recycled paper sludge".

Paper waste can be divided into two categories: coarse material and fine material. Coarse material mainly from the pulping and slagging stage, mostly stranded rope; fine material mainly from the cleaning and screening stage, fine material can be divided into light slag and heavy slag. After a reasonable process, most of the screened slag can be made into SRF fuel, which is used for incineration and power generation.

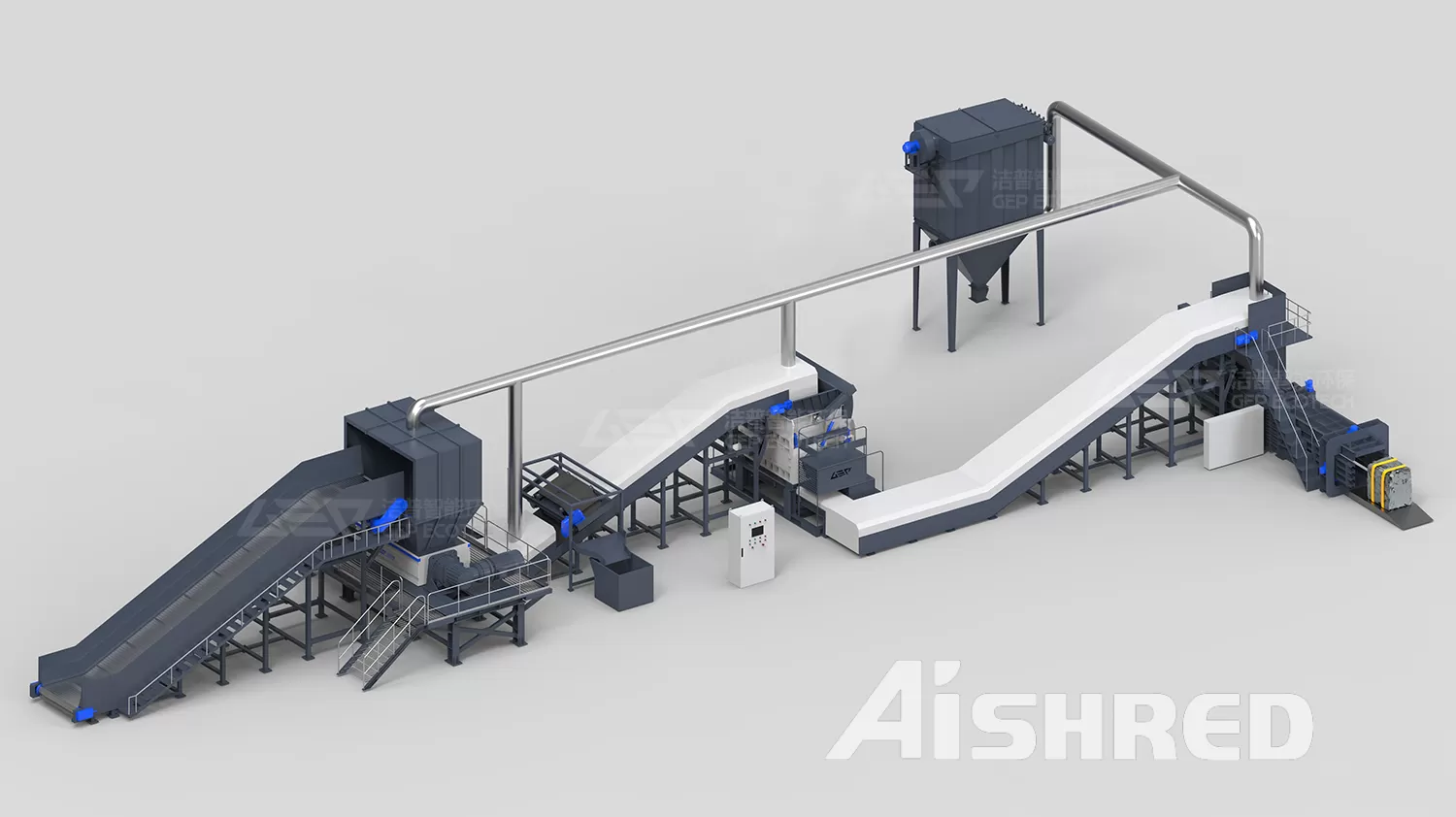

The waste shredding and processing system of environmental friendly paper mill adopts cutting-edge shredding pre-treatment and alternative fuel SRF preparation process. Through a whole set of large-scale processes such as dewatering, shredding, breaking up, dust removal and iron removal, the light slag, stranded rope and other solid wastes generated in the paper making process are transformed into alternative fuel for cogeneration. The whole processing process is highly automated and efficient. Taking a paper mill project as an example, the treatment system can produce 35 tons of fuel per hour, which can quickly and effectively realize the recycling of paper mill waste and bring low-cost operation and high-value recovery benefits to the customer.

The mill's recycling method for paper twist rope is to crush and sort it first, then pelletize it. Realize the recycling of waste resources. Iron wire can be crushed and taken out to sell scrap iron, and plastic can be used to reconstitute granules. Pulp can be used as recycled paper to realize resource recycling and protect the environment.

Adopting the shearing principle and independent drive of two shafts. During the production process, the material is automatically passed through the crusher cavity on both shafts for refinement and crushing.

The shredder is independently driven by two shafts, which can squeeze and shear the materials during production and can realize the automatic feeding function. The unique knife shaft structure, in the production process of low speed and high torque, will not appear tangled shaft or clogging equipment phenomenon, and improve the production efficiency. The equipment is suitable for crushing various materials with high toughness and high viscosity.