The recycling of PVC window frames plays a crucial role in sustainable waste management, with a focus on resource recovery and environmental conservation. This article explores the efficient process of shredding PVC window frames to extract valuable steel and aluminum, contributing to a more circular and eco-friendly approach to materials management.

Shredding Process

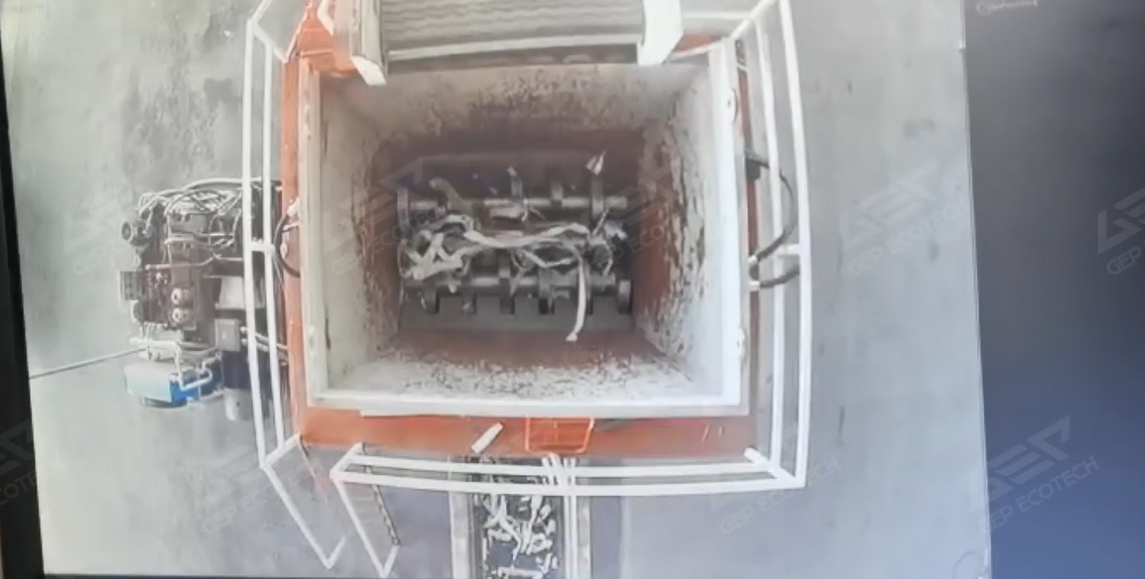

The initial step in recycling PVC window frames involves the use of advanced shredding equipment. A high-capacity industrial shredder is employed to break down the window frames into smaller, more manageable pieces. The shredding process not only reduces the volume of materials but also prepares them for subsequent separation and extraction stages.

Steel Extraction

Once the PVC window frames are shredded, the material undergoes a separation process to extract steel components. This is often achieved through the use of magnetic separators, which attract and isolate ferrous metals like steel. The extracted steel components can then be sent to steel mills for recycling, contributing to the conservation of natural resources and reducing the demand for new steel production.

Aluminum Extraction

In addition to steel, aluminum is a valuable component found in PVC window frames. Advanced sorting technologies, such as eddy current separators, are employed to efficiently extract aluminum from the shredded material. The separated aluminum can be recycled and repurposed, further promoting a closed-loop system for materials.

Benefits of Shredding PVC Window Frames and Extract Steel and Aluminum

- Environmental Benefits: The recycling of PVC window frames and the extraction of steel and aluminum offer several environmental benefits. By diverting these materials from landfills, the process reduces the environmental impact associated with traditional disposal methods. Recycling also conserves energy compared to the production of new materials, contributing to a reduction in greenhouse gas emissions.

- Economic Considerations: Recycling PVC window frames and extracting steel and aluminum present economic advantages as well. The recovered materials can be sold as valuable commodities in the recycling market, providing an economic incentive for waste management facilities and recycling operations. This economic aspect contributes to the viability and sustainability of the recycling process.

The efficient shredding of PVC window frames and the subsequent extraction of steel and aluminum showcase a technologically advanced and environmentally conscious approach to waste management. By incorporating these processes into the broader recycling framework, we not only reduce the environmental footprint associated with construction waste but also create opportunities for construction waste recovery and economic growth. Embracing such innovative recycling practices is essential for building a more sustainable and circular economy.