When a building is demolished or reconstructed, the resulting waste is referred to as construction and demolition (C&D) wastes. This waste includes concrete, bricks, wood, metals, tiles, pipes, and more. Recycling C&D debris is a profitable and eco-friendly business, converting these materials into recycled aggregates and valuable reclaimable resources.

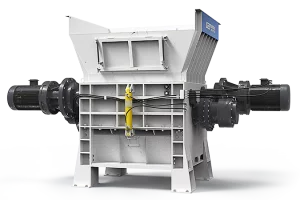

Recycling C&D waste is more complex compared to quarrying for raw materials, requiring advanced equipment and precise processes to manage vast and intricate material flows. This aims to reduce waste volume and increase recycling rates. Poor-quality equipment is prone to frequent breakdowns, elevating operational challenges and downtime, leading to unnecessary losses.

GEP ECOTECH offers robust solutions for C&D waste recycling, encompassing efficient sorting, effortless crushing, and precise screening, We are committed to achieving our 100% recycling goal.

Aggregate Recycling

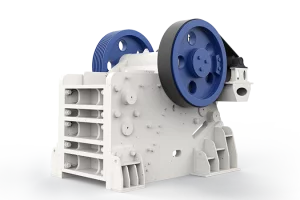

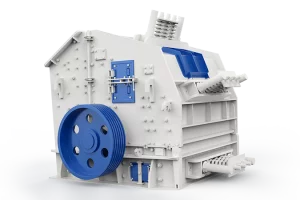

Recycled aggregates, the cornerstone product in the construction and demolition (C&D) debris recycling industry, serve a pivotal role much like conventional gravel by enhancing concrete strength. Derived from materials like concrete and asphalt found in construction waste, recycled aggregates are obtained through the process of sorting, crushing and grading.

With the continuous advancement in infrastructure development, the demand for aggregates has been steadily increasing. Recycled aggreate, renowned for its exceptional compaction, higher water absorption values, enhanced durability, and cost-effectiveness, has gained widespread popularity.

GEP ECOTECH's recycling management solutions assist manufacturers in responsibly and sustainably maximizing the production of clean recycled aggregates, reducing energy consumption and carbon footprint, thereby supporting the development of a circular economy.

Material Recovery

Construction and demolition waste often contain various materials. Random dumping or landfilling not only pollutes the environment but also wastes resources. We are committed to achieving 100% recycling of C&D Waste and provide various methods for recycling different materials.

Metals have always been one of the most valuable recyclable products. Large pieces of steel bars are usually manually sorted, while magnetic separators and eddy current separators installed on the production line continuously separate small pieces of metal from the waste stream.

Materials like plastics, leather, and paper have always posed challenges in handling as improper treatment can contaminate recycled aggregates. We employ multiple sorting techniques to separate these materials and process them into Refuse-Derived Fuel (RDF).

Large wooden pieces are manually sorted, while smaller ones are separated using specialized equipment, serving as RDF or raw material for recycled wood.

Materials such as gypsum, clay, and bricks shouldn't be landfilled either. Our production line is capable of transforming them into recycled bricks or utilizing them as base materials for roads, maximizing their reuse.

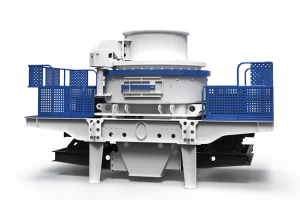

Mobile Solution

For numerous construction and demolition waste recycling projects, mobile versions of equipment are preferred because they can operate on-site, saving substantial transportation costs. Moreover, their ability to be relocated according to site requirements contributes to improved work efficiency.

GEP ECOTECH's mobile equipment embodies this flexibility and versatility. Their equipment includes versions installed on tracks and wheels, offering primary, secondary, and tertiary crushing functions. It also includes mobile screening and feeding devices, meeting the diverse requirements of demolition projects for mobile equipment.