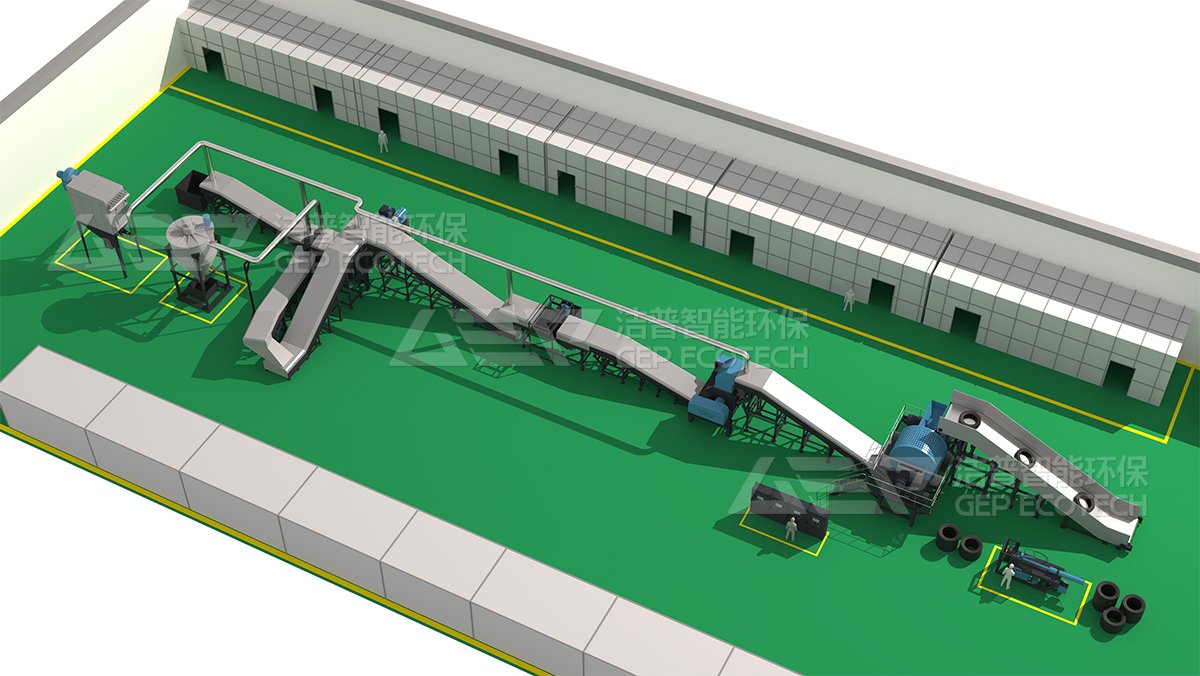

Waste tire recycling machine for rubber powder, also known as rubber powder production line, is designed to convert waste tires into rubber powder or granules for various applications. These machines typically go through several stages to process tires into usable rubber powder. Here are some key components and steps involved in the process:

Rubber Powder Production Line

1. Tire Shredding:

Tire Cutter/Shredder: Used to cut or shred tires into smaller pieces or strips, increasing the surface area for subsequent processing.

2. Granulation or Grinding:

Rubber Grinder: Further reduces the shredded tires into granules or fine rubber powder.

3. Magnetic Separation:

Magnetic Separator: Removes steel wires and other metallic components from the rubber material obtained from the grinding process.

4. Fiber Separation (Optional):

Fiber Separator: Separates and removes fiber materials from the rubber powder, depending on the desired purity of the final product.

5. Fine Powder Processing (Optional):

Fine Grinding/Milling Equipment: Some systems include additional steps for further refining rubber powder into finer particles for specific applications.

These tire rubber powder machines come in various capacities, ranging from small-scale units suitable for handling a few tires per hour to large industrial-scale systems capable of processing a significant volume of tires daily.

The waste tire recycling machine for rubber powder plays a crucial role in converting used tires into valuable resources, contributing to both waste reduction and material recycling efforts. The rubber powder recovered from waste solid tires has many uses, If you want to know more, please read the following article about the tyre rubber powder uses.