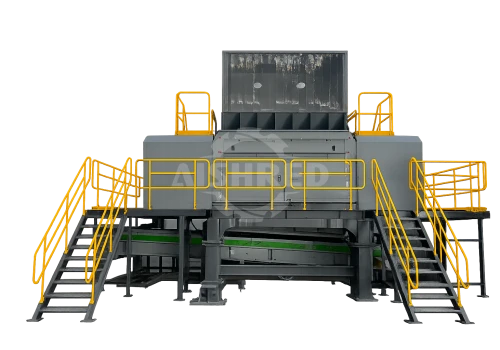

By the end of 2025, we successfully completed the installation and commissioning of a new industrial plastic shredding line in the United Arab Emirates. This line is specifically designed for processing PP/PS plastic hangers with metal hooks, while also capable of handling other common plastic waste. It aims to provide a reliable technical solution for volume reduction, separation of metal impurities, and stable output of clean, recyclable materials. Below is a detailed introduction to this plastic shredding line.

Core Equipment: GEP ECOTECH Third-Generation Single-Shaft Grinder

At the heart of this shredding line is a heavy-duty, industrial-grade single-shaft plastic grinder, custom-designed for challenging materials such as metal-hook-equipped plastic hangers. The grinder incorporates GEP ECOTECH's latest third-generation technology, which delivers broader material adaptability, stronger shredding performance, and effectively resolves common operational issues like material clogging and inconsistent feeding.

This customized model maintains a stable throughput of up to 1,000 kg per hour. By utilizing interchangeable screen meshes (typically in the 20–50 mm range), the system allows precise control over output particle size, producing uniform and contaminant-free plastic regrind ready for pelletizing or direct sale as high-quality recycled material.

Auxiliary Equipment: Magnetic Separator, Conveyor

To ensure high efficiency and material purity, the recycling line is equipped with a complete set of auxiliary equipment. A feeding conveyor system allows for manual feeding or hopper-based automatic feeding, ensuring continuous and stable material input.

After shredding, the mixed output passes through a self-cleaning overband magnetic separator, which automatically removes metal hooks, clips, and other ferrous contaminants. This step is critical for protecting downstream equipment and increasing the value of the recycled plastic.

At the end of the line, a big bag filling station is integrated to enable clean, centralized collection and packaging of shredded material.

GEP ECOTECH will continue to monitor the actual operating performance of this production line in the UAE to help customers achieve stable production and improved efficiency. If you have any needs related to plastic crushing and recycling, please feel free to contact us for customized solutions.